Η επιστήμη πίσω από την ηλεκτροφορητική επικάλυψη και την προστασία από διάβρωση

Κατανόηση της λειτουργίας της e-coat (ηλεκτροφορητικής καταβύθισης σε αγώγιμες επιφάνειες)

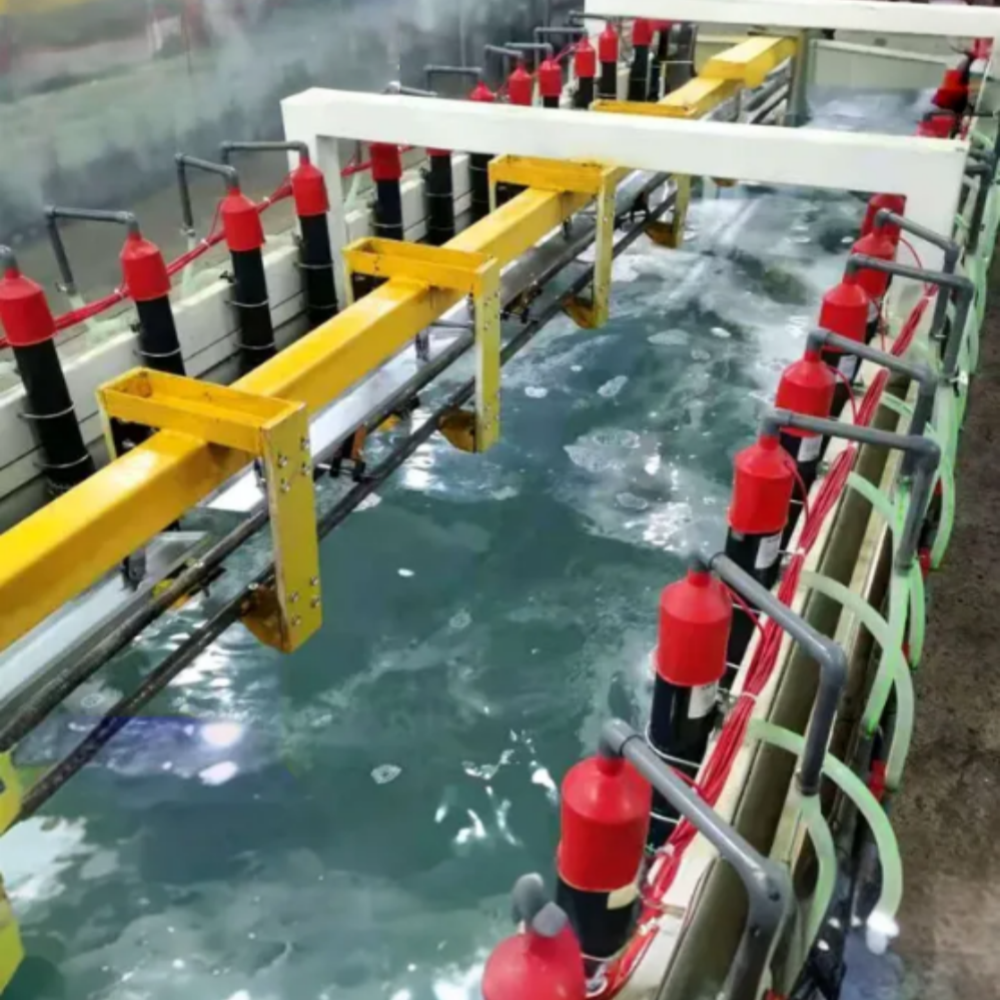

Η διαδικασία της ηλεκτροφόρησης λειτουργεί με την εφαρμογή ηλεκτροστατικών δυνάμεων για την επικάλυψη προστατευτικών στρωμάτων σε μεταλλικές επιφάνειες. Τα εξαρτήματα βυθίζονται σε διάλυμα ηλεκτροφόρησης, όπου η συνεχής ρεύμα προκαλεί τη μετακίνηση ιόντων, τραβώντας τα σωματίδια της μπογιάς προς την επιφάνεια, μέχρι να ενωθούν σχηματίζοντας ένα παχύ στρώμα που προσκολλάται καλά. Οι παραδοσιακές εποξειδικές επιστρώσεις αφήνουν συχνά μικρές οπές, αλλά αυτές οι ηλεκτροχημικές μέθοδοι καταφέρνουν να καλύψουν αυτά τα μικροσκοπικά κενά που δεν μπορούμε να δούμε με γυμνό μάτι. Σύμφωνα με πρόσφατες μελέτες που δημοσιεύθηκαν στο Nature το 2025, δημιουργείται πολύ καλύτερη στεγανοποίηση από την υγρασία και τη χημική διάβρωση με την πάροδο του χρόνου σε σχέση με παλαιότερες τεχνικές.

Ο ρόλος του ηλεκτρικού φορτίου στην ηλεκτροφόρηση και η μετανάστευση ιόντων κατά την εναπόθεση

Η ελεγχόμενη κατανομή του φορτίου αποτελεί τον πυρήνα αυτής της διαδικασίας. Βασικά, τα ανοδικά μέταλλα προσελκύουν τα αρνητικά φορτισμένα πολυμερή σωματίδια, ενώ οι καθοδικές επιφάνειες αρπάζουν τα θετικά φορτισμένα αντίστοιχά τους. Το αποτέλεσμα; Μια πολύ πιο ομοιόμορφη επικάλυψη κατακλίνεται σε όλες τις επιφάνειες, γεγονός που σημαίνει λιγότερα ελαττώματα και καλύτερη συνολική ποιότητα. Σύμφωνα με πρόσφατες μελέτες, αυτή η μέθοδος μειώνει τη διείσδυση ηλεκτρολύτη κατά περίπου 60 τοις εκατό σε σχέση με παλαιότερες μη ηλεκτροστατικές τεχνικές. Και αυτό είναι λογικό, αφού ουσιαστικά σταματά τις ηλεκτροχημικές αντιδράσεις πριν αυτές προκαλέσουν προβλήματα που σχετίζονται με τη διάβρωση. Πολλοί κατασκευαστές έχουν παρατηρήσει αυτά τα οφέλη από πρώτο χέρι, αφού μεταπήδησαν από παραδοσιακές προσεγγίσεις.

Καθοδική ηλεκτροφόρηση (Καθοδική Επικάλυψη) για Ανώτερη Προστασία από Διάβρωση

Στην καθαρτική ηλεκτροβαφή, το τεμάχιο λειτουργεί ως η κάθοδος, προσελκύοντας αντιδιαβρωτικά σωματίδια με θετικό φορτίο. Αυτή η διάταξη εξουδετερώνει τα υδροξείδια ιόντα στη διεπαφή του μετάλλου – γνωστούς καταλύτες για αποτυχία στην πρόσφυση. Οι αυτοκινητοβιομηχανίες που χρησιμοποιούν γραμμές καθαρτικής ηλεκτροβαφής αναφέρουν 75% λιγότερες αξιώσεις εγγύησης σχετικές με διάβρωση κατά τη διάρκεια 10ετούς περιόδου χρήσης, κάτι που δείχνει την αποτελεσματικότητά της σε απαιτητικά περιβάλλοντα.

Ομοιόμορφη Κάλυψη: Πώς οι Γραμμές Ηλεκτροφορητικής Βαφής Μεγιστοποιούν την Προστασία της Επιφάνειας

Η Δυνατότητα της Ηλεκτροβαφής να Παρέχει Πλήρη και Συνεχή Κάλυψη για Αντοχή στη Διάβρωση

Η ηλεκτροφορητική βαφή επιτυγχάνει ανωτερότερη αντοχή στη διάβρωση μέσω ομοιόμορφης καταβολής υδατοδιαλυτής βαφής μέσω ηλεκτρικής προσέλκυσης. Αυτό εξασφαλίζει ομοιόμορφη κάλυψη σε ακμές, κοιλότητες και επίπεδες επιφάνειες, εξαλείφοντας τα σημεία με λεπτή επικάλυψη που υπονομεύουν την προστασία – ένα βασικό μειονέκτημα των χειροκίνητων μεθόδων εφαρμογής.

Ξεπερνώντας τη Γεωμετρική Πολυπλοκότητα: Ομοιόμορφη Επικάλυψη σε Πολύπλοκα και Εσοχικά Τμήματα

Τα αυτοματοποιημένα συστήματα ηλεκτροφόρησης ξεχωρίζουν στην προστασία πολύπλοκων μεταλλικών εξαρτημάτων. Η βύθιση στο λουτρό επιτρέπει στις ηλεκτρικές διαβαθμίσεις να καθοδηγούν την επικάλυψη σε εγκοπές μέχρι και 0,5 mm, συμπεριλαμβανομένων των σπειροειδών συνδέσμων, των κοιλοδοκών και των αρθρώσεων με πολλαπλές γωνίες. Αυτό εξασφαλίζει πλήρη εγκλεισμό και συνεχή προστασία από υγρασία και διαβρωτικά στοιχεία.

Σύγκριση με την Παραδοσιακή Βαφή: Γιατί οι Μέθοδοι Ψεκασμού Υστερούν στην Ομοιομορφία

Η βαφή με ψεκασμό εξαρτάται από την τεχνική του χειριστή και τις ρευστομηχανικές διεργασίες, συχνά με αποτέλεσμα σκιασμένες περιοχές με ανεπαρκή κάλυψη. Ο υπερψεκασμός σπαταλά το 30–40% του υλικού, ενώ οι ανομοιότητες στη ροή του αέρα οδηγούν σε ακανόνιστο πάχος φιλμ. Αντίθετα, η ηλεκτροχημική διαδικασία ηλεκτροφόρησης ρυθμίζεται από μόνη της για να διατηρεί ομοιομορφία πάχους ±2 μm σε όλες τις γεωμετρίες.

Στοιχείο Πληροφόρησης: 98% Κάλυψη Επιφάνειας στην Αυτοματοποιημένη Ηλεκτροφόρηση έναντι 70–80% στον Ψεκασμό

Ανεξάρτητες δοκιμές επιβεβαιώνουν το πλεονέκτημα κάλυψης της ηλεκτροφόρησης:

- 98,2% κάλυψη επιφάνειας σε αυτοματοποιημένες γραμμές ηλεκτροφόρησης (συμμόρφωση με το πρότυπο ISO 2178)

- κάλυψη 72–79% σε συμβατικούς θαλάμους ψεκασμού (σύμφωνα με επιθεωρήσεις ASTM D3276)

Η διαφορά αυτή της τάξης του 20–25% επηρεάζει σημαντικά τη διάρκεια: τα επικαλυμμένα με ηλεκτροφόρηση εξαρτήματα αντέχουν πάνω από 1.000 ώρες σε δοκιμές αλατόλουτρου, σε σύγκριση με 300–500 ώρες για τα αντίστοιχα βαψιμένα με ψεκασμό (Βιομηχανική Ανάλυση Επιστρώσεων 2023).

Επίστρωση Ηλεκτροφόρησης έναντι Εναλλακτικών Μεθόδων: Αντοχή και Απόδοση

Ηλεκτροφόρηση έναντι Συμβατικού Βαψίματος: Αντοχή στη Διάβρωση και Μακροχρόνια Αντοχή σε Σύγκριση

Η ηλεκτροφόρηση (e-coating) υπερτερεί της συμβατικής βαφής με ψέκασμα όσον αφορά την προστασία από τη σκουριά, λόγω του τρόπου με τον οποίο κατακαθίζεται το υλικό μέσω ηλεκτρισμού. Οι τεχνικές ψεκασμού καταφέρνουν συνήθως κάλυψη από 70 έως περίπου 80 τοις εκατό, αφήνοντας απροστάτευτες τις δύσκολες περιοχές, όπως γωνίες και σχισμές. Η αυτοματοποιημένη ηλεκτροφόρηση επιτυγχάνει πολύ καλύτερα αποτελέσματα, καλύπτοντας περίπου το 98% των επιφανειών συνολικά, σύμφωνα με πρόσφατα δεδομένα της βιομηχανίας για το 2023. Σε δοκιμές με αλμυρή ομίχλη, τα επικαλυμμένα με ηλεκτροφόρηση εξαρτήματα αντέχουν πολύ περισσότερο από 1.000 ώρες πριν εμφανίσουν οποιοδήποτε σημάδι σκουριάς. Τα αντίστοιχα αντικείμενα που έχουν βαφεί με ψέκασμα αρχίζουν να διαβρώνονται μεταξύ 300 και 400 ωρών αργότερα. Ένα ακόμη μεγάλο πλεονέκτημα είναι ότι αυτά τα πολυμερή επιστρώματα προσφέρουν περίπου 40% ισχυρότερη πρόσφυση σε σχέση με τη βαφή με ψέκασμα, γι’ αυτό δεν αποφλοιώνονται εύκολα όταν υφίστανται κρούσεις ή άγρια χειρισμούς κατά τη μεταφορά και την εγκατάσταση.

Αποδεδειγμένη απόδοση σε σκληρά περιβάλλοντα: Εφαρμογές σε αυτοκινητοβιομηχανία και βιομηχανία

Οι κατασκευαστές αυτοκινήτων έχουν διαπιστώσει ότι τα εξαρτήματα του πλαισίου με επίστρωση emulsion coat παρουσιάζουν περίπου 60% λιγότερα προβλήματα εγγύησης σε σχέση με εκείνα που επιστρώνονται με σκονιστή βαφή, ακόμη και μετά από πέντε ολόκληρα χρόνια έκθεσης στο χαλίκι του δρόμου. Οι διαχειριστές αιολικών πάρκων στο ανοιχτό πέλαγος παρατηρούν σχεδόν καθόλου σημεία σκουριάς μέσα στα κιβώτια ταχυτήτων των ανεμογεννητριών, παρότι οι μηχανές αυτές εκτίθενται συνεχώς στον αλμυρό αέρα της θάλασσας. Γιατί συμβαίνει αυτό; Λοιπόν, η emulsion coat λειτουργεί καλύτερα στην κάλυψη όλων εκείνων των δύσκολων σημείων, όπως τα σημεία συγκόλλησης και τις στενές γωνίες, στα οποία οι συμβατικές επιστρώσεις τάσονται να συγκεντρώνονται λανθασμένα ή απλώς να σπάνε όταν οι θερμοκρασίες μεταβάλλονται σημαντικά κατά τη λειτουργία.

Εμπόδια στην Υιοθέτηση: Γιατί Κάποιες Βιομηχανίες Δείχνουν Δισταγμό Παρά τα Πλεονεκτήματα της Eπίστρωσης emulsion coat

Ενώ η τεχνολογία λειτουργεί καλά, πολλοί μεσαίου μεγέθους κατασκευαστές αντιμετωπίζουν ακόμη προβλήματα με το κόστος. Περίπου το 38% δηλώνει ότι η αναβάθμιση των εγκαταστάσεών τους κυμαίνεται από 200 χιλιάδες έως μισό εκατομμύριο δολάρια μόνο για βασικά συστήματα. Επιπλέον, οι μεγάλοι βιομηχανικοί θερμοποιητές καταναλώνουν 15 έως 25 τοις εκατό περισσότερη ενέργεια σε σχέση με τα συμβατικά θαλάμους ψεκασμού. Υπάρχει ακόμη ένα πρόβλημα: οι περισσότερες συμβατικές διαδικασίες ηλεκτροβαφής δεν λειτουργούν σε μη αγώγιμα υλικά, όπως ορισμένα πλαστικά σύνθετα, οπότε οι εταιρείες συχνά καταλήγουν να χρησιμοποιούν αυτές τις πολύπλοκες υβριδικές προσεγγίσεις. Ωστόσο, αν εξετάσει κανείς την ευρύτερη εικόνα, μελέτες δείχνουν ότι οι επιχειρήσεις ανακτούν συνήθως τα χρήματά τους μέσα σε τρία έως πέντε χρόνια, καθώς ξοδεύουν λιγότερα για εργασίες επαναβάφσης και τα προϊόντα τους διαρκούν περισσότερο στο πεδίο πριν χρειαστεί συντήρηση.

Η Διαδικασία Ηλεκτροβαφής: Από την Προεπεξεργασία έως τον Θερμοποίηση για Προστασία από τη Σκουριά

Αναλυτική Περιγραφή της Διαδικασίας Ηλεκτροφορητικής Επικάλυψης

Ένα σύστημα επικάλυψης με ηλεκτροφόρηση συνδυάζει προσεκτικά βήματα χημικής επεξεργασίας με ελεγχόμενες μεθόδους ηλεκτρικής εφαρμογής. Η διαδικασία ξεκινά συνήθως με έναν αλκαλικό καθαρισμό για την απομάκρυνση λιπαντικών υπολειμμάτων από τις μεταλλικές επιφάνειες. Στη συνέχεια ακολουθεί η φωσφάτωση, η οποία δημιουργεί μικροσκοπικές κρυσταλλικές δομές που βοηθούν την επικάλυψη να προσφύεται καλύτερα στο υπόστρωμα. Όταν τα εξαρτήματα μπαίνουν στη δεξαμενή επικάλυψης, δέχονται τάση μεταξύ 100 και 300 βολτ, η οποία ωθεί τα σωματίδια της ρητίνης προς κάθε επιφάνεια, συμπεριλαμβανομένων των δύσκολα προσπελάσιμων γωνιών και σχισμών. Μετά την ξέπλυση της περίσσειας ύλης που δεν χρησιμοποιήθηκε, τα περισσότερα συστήματα ανακτούν περίπου το 95% της περίσσειας πρώτης ύλης πριν προχωρήσουν στο τελικό στάδιο. Σε θερμοκρασίες μεταξύ 160 και 200 βαθμών Κελσίου, τα πολυμερικά μόρια συνδέονται μεταξύ τους, δημιουργώντας το δυνατό προστατευτικό στρώμα που γνωρίζουμε ότι διαρκεί πολύ περισσότερο σε σχέση με τις παραδοσιακές επικαλύψεις.

Πώς κάθε στάδιο συμβάλλει στη μακροχρόνια προστασία από σκουριά και διάβρωση

Η προεπεξεργασία με φωσφορικό ψευδάργυρο δημιουργεί μια βάση που εμποδίζει τη διαδικασία της διάβρωσης να ξεκινήσει. Κατά τη διαδικασία επικάλυψης, ένα φαινόμενο γνωστό ως το φαινόμενο Faraday βοηθά στη διατήρηση σχεδόν σταθερού πάχους της επικάλυψης, στα ±2 μικρόμετρα, όταν εργαζόμαστε με επιστρώσεις πάχους από 10 έως 40 μικρόμετρα. Η συνέπεια αυτή είναι πολύ σημαντική, καθώς εμποδίζει τη διάβρωση να εμφανιστεί κάτω από την επίστρωση. Όταν αυτές οι επιστρώσεις ξηραίνονται σωστά, δημιουργούν ένα υδατοαπωθητικό φράγμα που εμποδίζει την είσοδο ηλεκτρολυτών. Τα επιστρωμένα εξαρτήματα κατά κανόνα διαρκούν περισσότερο από 1.000 ώρες στις σκληρές δοκιμές ψεκασμού αλατιού που καθορίζονται από τα πρότυπα ASTM B117. Αυτό είναι πολύ καλύτερο από τα αποτελέσματα που επιτυγχάνουν οι περισσότερο συνηθισμένες βαφές ψεκασμού, οι οποίες συνήθως αντέχουν μόνο περίπου 300 έως 500 ώρες πριν εμφανιστούν σημάδια ζημιάς.

Περιστατικό Μελέτης: Κατασκευαστής Αυτοκινήτων Μειώνει τις Εγγυήσεις για Διάβρωση στον Τομέα κατά 60% Μετά τη Μετάβαση σε Επικάλυψη Βυθισμού

Ένας μεγάλος κατασκευαστής αυτοκινητοβιομηχανικών εξαρτημάτων ξεφορτώθηκε τα ενοχλητικά κενά βαφής στις μεντεσέδες των πορτών, όταν προχώρησε στη μετάβαση σε τεχνολογία e-coating. Εγκατέστησαν αισθητήρες ρευμάτων Foucault στη γραμμή παραγωγής για να ελέγχουν ότι κάθε εξάρτημα επικαλύπτεται σωστά. Μετά από 18 μήνες, συνέβη κάτι ενδιαφέρον: οι διεκδικήσεις εγγύησης που σχετίζονταν με διάβρωση μειώθηκαν από περίπου 12,7% σε μόλις 5,1%, σύμφωνα με την περσινή έκθεση του κλάδου. Αρκετά εντυπωσιακά για τη γραμμή παραγωγής! Επιπλέον, η νέα διάταξη κλειστού κυκλώματος φιλτραρίσματος μείωσε τις εκπομπές VOC κατά απίστευτο 85% σε σχέση με τις παραδοσιακές μεθόδους που βασίζονται σε διαλύτες. Όχι μόνο καλύφθηκαν όλες οι απαραίτητες απαιτήσεις ανθεκτικότητας, αλλά επίσης επιτεύχθηκαν σημαντικά περιβαλλοντικά κριτήρια με τα οποία πολλοί κατασκευαστές αγωνίζονται αυτές τις μέρες.

Τμήμα Γενικών Ερωτήσεων

Τι είναι η ηλεκτροφορητική επικάλυψη;

Η ηλεκτροφορητική επικάλυψη ή e-coat είναι μια μέθοδος που χρησιμοποιεί ηλεκτροστατικές δυνάμεις για την εφαρμογή επικαλύψεων σε μεταλλικές επιφάνειες, δημιουργώντας προστατευτική στιβάδα από διάβρωση και ζημιές.

Γιατί η ηλεκτροφόρηση είναι καλύτερη από τις παραδοσιακές μεθόδους βαφής;

Η ηλεκτροφόρηση προσφέρει ανώτερη προστασία από διάβρωση, με κάλυψη επιφάνειας 98% και συνεχή πάχος που οι παραδοσιακές μέθοδοι βαφής δεν μπορούν να επιτύχουν.

Ποια είναι τα πλεονεκτήματα της καθαφορητικής ηλεκτροβαφής;

Η καθαφορητική ηλεκτροβαφή παρέχει εξαιρετική σύνδεση και ελαχιστοποιεί θέματα που σχετίζονται με διάβρωση, με σημαντικές μειώσεις στα αιτήματα εγγύησης από τους κατασκευαστές.

Πίνακας Περιεχομένων

- Η επιστήμη πίσω από την ηλεκτροφορητική επικάλυψη και την προστασία από διάβρωση

-

Ομοιόμορφη Κάλυψη: Πώς οι Γραμμές Ηλεκτροφορητικής Βαφής Μεγιστοποιούν την Προστασία της Επιφάνειας

- Η Δυνατότητα της Ηλεκτροβαφής να Παρέχει Πλήρη και Συνεχή Κάλυψη για Αντοχή στη Διάβρωση

- Ξεπερνώντας τη Γεωμετρική Πολυπλοκότητα: Ομοιόμορφη Επικάλυψη σε Πολύπλοκα και Εσοχικά Τμήματα

- Σύγκριση με την Παραδοσιακή Βαφή: Γιατί οι Μέθοδοι Ψεκασμού Υστερούν στην Ομοιομορφία

- Στοιχείο Πληροφόρησης: 98% Κάλυψη Επιφάνειας στην Αυτοματοποιημένη Ηλεκτροφόρηση έναντι 70–80% στον Ψεκασμό

-

Επίστρωση Ηλεκτροφόρησης έναντι Εναλλακτικών Μεθόδων: Αντοχή και Απόδοση

- Ηλεκτροφόρηση έναντι Συμβατικού Βαψίματος: Αντοχή στη Διάβρωση και Μακροχρόνια Αντοχή σε Σύγκριση

- Αποδεδειγμένη απόδοση σε σκληρά περιβάλλοντα: Εφαρμογές σε αυτοκινητοβιομηχανία και βιομηχανία

- Εμπόδια στην Υιοθέτηση: Γιατί Κάποιες Βιομηχανίες Δείχνουν Δισταγμό Παρά τα Πλεονεκτήματα της Eπίστρωσης emulsion coat

-

Η Διαδικασία Ηλεκτροβαφής: Από την Προεπεξεργασία έως τον Θερμοποίηση για Προστασία από τη Σκουριά

- Αναλυτική Περιγραφή της Διαδικασίας Ηλεκτροφορητικής Επικάλυψης

- Πώς κάθε στάδιο συμβάλλει στη μακροχρόνια προστασία από σκουριά και διάβρωση

- Περιστατικό Μελέτης: Κατασκευαστής Αυτοκινήτων Μειώνει τις Εγγυήσεις για Διάβρωση στον Τομέα κατά 60% Μετά τη Μετάβαση σε Επικάλυψη Βυθισμού

- Τμήμα Γενικών Ερωτήσεων