Provide solutions according to customer requirements

Production within 45-90 days, 100% on-time delivery rate

Delivery and professional door-to-door installation

12-month warranty on core accessories

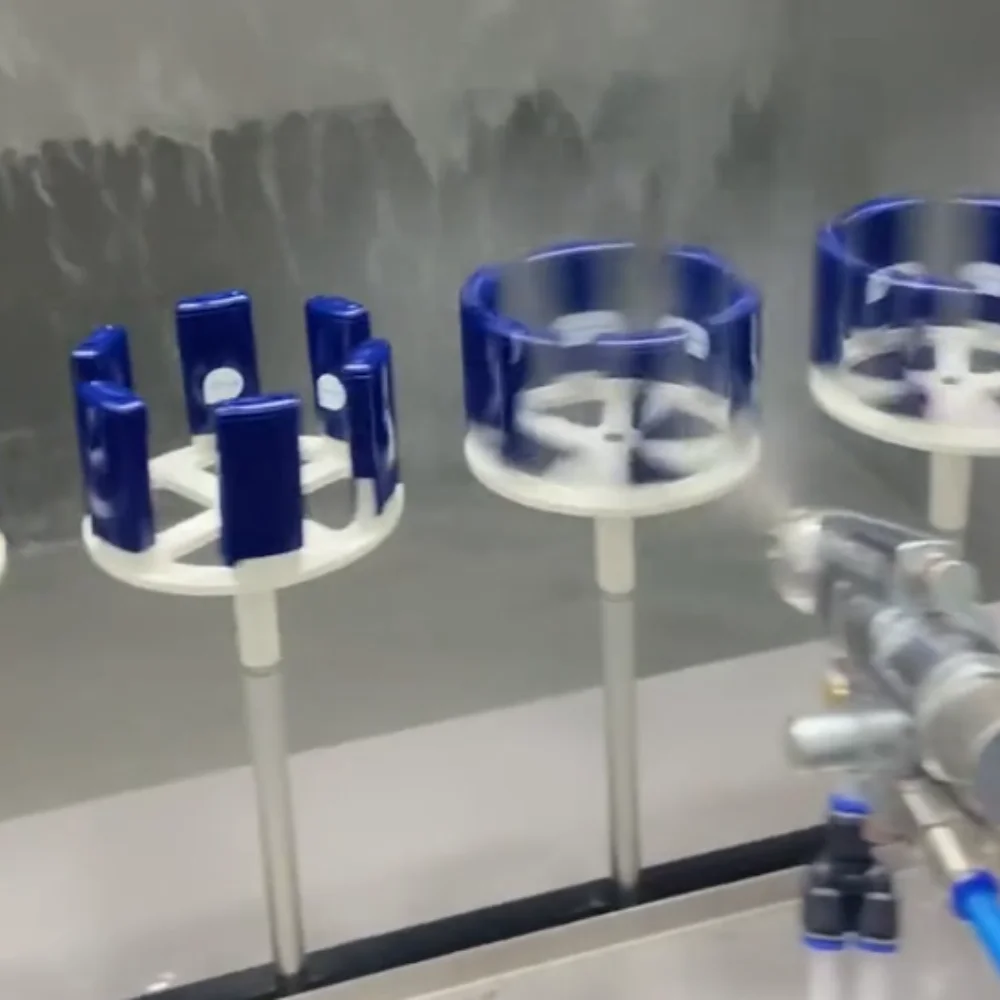

Fully automatic electrostatic powder coating line, equipped with integrated automatic conveying system, can work continuously under the program of electronic control system. Ensure efficient and energy-saving operation.

The efficient recovery system increases the powder utilization to the limit and reduces costs.

Automated Advantages of Electronic Component Painting

In the spray painting industry, the advantages of automated spray painting are already significant. Statistics show that the defect rate of automated spray painting lines is only 0.1%, compared to as high as 5% for manual painting, significantly reducing product rework costs. Manual spray painting requires precise accuracy, and experienced spray painters, even with monthly salaries exceeding 10,000 yuan, are still in short supply.

Furthermore, long-term exposure to paint and its volatile harmful substances can lead to chronic pharyngitis, pneumonia, and other illnesses. In terms of efficiency, automated spray painting lines can spray tens of thousands of components per hour, three to five times faster than manual labor. They also precisely control paint usage through programming and recycle powder, reducing paint waste by 80%. With electronic components currently in short supply, automated spray painting, which ensures precision while controlling costs, has become a key area for industry upgrades.

Manual painting was once the mainstream in the spray painting industry, but the widespread adoption of automation is radically changing this landscape. Data shows that automated spray painting lines are three times more efficient than manual painting for automobile chassis, and their painting tolerances are kept to within 0.5 mm, far lower than the average manual error of 2 mm.

Manual painting not only requires a large number of skilled workers (who generally command high monthly salaries and are difficult to recruit), but is also prone to fatigue, leading to large variations in the painting of parts and a high defect rate, with a loss rate of approximately 5%.

Automated spray painting lines, on the other hand, can operate 24 hours a day, with a loss rate of 0.1%. Furthermore, manual handling of heavy parts can lead to occupational hazards such as lumbar injuries, while automated robotic arms completely eliminate these risks. Clearly, the transition to automation in automotive assembly is both a necessity for improving quality and an inevitable development of the industry.

1. Basic composition

Automatic powder spraying line usually consists of multiple core links to form a coherent production process:

1). Pre-treatment system

- Function: remove impurities such as oil, rust, oxide scale on the surface of the workpiece to enhance the adhesion of the powder coating.

- Common processes: pre-degreasing, main degreasing, water washing, surface conditioning, phosphating (or passivation), pure water washing, etc. Some production lines will adjust the process according to the material of the workpiece (such as aluminum alloy).

- Automation features: The workpiece is automatically transported by hanging chains or conveyor belts, and each process tank is equipped with automatic liquid replenishment, temperature control, filtration and other devices.

2). Drying and curing system

- Function: Dry the water from the pre-treated workpiece to prepare for spraying; after spraying, the powder is melted into a uniform coating through high-temperature curing.

- Equipment form: Most of them are tunnel ovens, which use electric heating, gas heating or hot air circulation, and the temperature can be precisely controlled (usually 180-220℃, adjusted according to the type of powder).

3). Powder spraying system

- Core equipment: automatic powder spray gun (such as electrostatic spray gun), powder recovery device, powder supply center.

- Working principle: The powder is negatively charged by the electrostatic generator, and the workpiece is positively charged when it is grounded. The powder is adsorbed on the surface of the workpiece under electrostatic attraction; the excess powder can be reused after filtering by the recovery system to reduce waste.

- Automatic control: The spray gun position and spraying parameters (voltage, current, powder output) can be set through PLC programming to adapt to different workpiece shapes and sizes.

4). Conveying system

- Function: The workpiece is transported between each process at a set speed to ensure production continuity.

- Common forms: hanging conveyor chain (suitable for large and special-shaped parts), ground conveyor belt (suitable for flat workpieces), the speed can be adjusted according to the production rhythm.

5). Control system

- With PLC as the core, combined with touch screen to realize parameter setting, process monitoring, fault alarm and other functions, some high-end production lines can be connected to MES system to realize intelligent management.

2. Workflow

1). Loading: Manual or robot hangs the workpiece to be processed on the hanger of the conveyor chain.

2). Pretreatment: The workpiece goes through degreasing, water washing, phosphating and other processes in sequence, and automatically completes surface cleaning and pretreatment.

3). Drying: Enter the oven to remove moisture and ensure the surface is dry.

4). Powder spraying: The workpiece enters the powder spraying room, and the automatic powder spraying gun sprays according to the preset program, and the excess powder is recycled.

5). Curing: The workpiece after spraying enters the curing furnace, and the powder melts, flows and solidifies into a coating at high temperature.

6). Cooling: The coating is fixed by natural cooling or forced air cooling.

7). Unloading: Manual or robot removes the finished product from the hanger to complete the production.

3. Advantages

- High efficiency: Automated continuous production, the hourly production capacity of a single line can reach hundreds to thousands of pieces, far exceeding manual spraying.

- Environmental protection: Powder coatings do not contain solvents (VOCs emissions are extremely low), and excess powder can be recycled, meeting international environmental protection requirements.

- Stable coating quality: Spraying parameters are precisely controlled, coating thickness is uniform (usually 50-150μm), and adhesion, corrosion resistance and other properties are excellent.

- Cost saving: Reduced dependence on labor, high powder utilization rate (up to more than 98%), and long-term operating costs are lower than traditional liquid spraying.

4. Application areas

- Automotive industry: frames, wheels, bumpers and other parts.

- Home appliance industry: refrigerator, washing machine shell, air conditioner outdoor unit, etc.

- Building materials industry: aluminum alloy profiles, steel doors and windows, guardrails, etc.

- General industry: tool boxes, instrument shells, medical devices, etc.

Automatic powder spraying lines have become the mainstream choice for modern industrial surface treatment due to their high efficiency, environmental protection and high quality. They are especially indispensable in fields with high requirements on coating performance and production scale.

Product advantages

1. Advanced technology research and development capabilities

- Core accessories and equipment are all developed by the factory: automatic spray guns, the first domestic 110KV high-performance double-voltage high-voltage module and other cutting-edge technologies can improve powder spraying efficiency and coating effects; and an efficient powder recovery system has been developed to increase the powder recovery rate to 99%, significantly reducing powder costs.

- Introducing intelligent technology: Using AI technology to support the spraying process, optimizing spraying parameters through intelligent algorithms, and realizing automated and precise spraying. The Internet of Things technology can also be used to allow data between devices to communicate, helping customers to monitor and adjust the spraying process in real time, and improve production efficiency and product quality.

- Keep up with industry trends: Pay attention to the development of new technologies and new materials in the powder spraying industry, and introduce new technologies such as low-temperature curing powder coatings in a timely manner to meet customers' needs for special coatings or energy-saving production.

2. Excellent product quality

- Ensure that the coating has good adhesion, corrosion resistance, wear resistance, etc. The spraying products that can be provided to customers in the new energy field enable the coating to withstand salt spray tests for more than 3,000 hours, meeting the needs of harsh outdoor environments.

- Through advanced automation equipment and precise control systems, strictly control various parameters in the spraying process, reduce product quality fluctuations, and ensure that the quality of each batch of products can meet high standards.

- Make the coating surface flat, smooth, and color-free, which can meet customers' high-quality requirements for product appearance. For some products such as home appliance shells with high appearance requirements, it can provide delicate and beautiful coating effects.

3. Efficient production capacity

- Reasonably plan the layout of the production line and adopt advanced conveying systems to reduce the transmission time of workpieces between various processes and improve production rhythm. At the same time, through the automated control system, the seamless connection of various processes is achieved to improve overall production efficiency.

- With the ability to quickly switch product models and specifications, the spraying process and equipment parameters can be adjusted in time according to customer order requirements, which can meet large-scale batch production and small batch and multi-variety orders.

4. Perfect service system

- In the early stage, according to the customer's workpiece size, shape, production capacity requirements and special process requirements, provide free personalized plant planning and process simulation, and design exclusive spraying production line solutions.

- Provide 24-hour customer service response to quickly solve problems encountered by customers during the production process. We promise to "repair first and then replace", and replace core components free of charge during the warranty period, so that customers have no worries.

- Provide operators training for customers to familiarize them with equipment operation and maintenance knowledge, and improve customers' production efficiency and product quality. At the same time, we regularly visit customers to provide technical upgrade suggestions and optimization solutions.

5. Strict environmental protection measures

- Use advanced waste gas treatment equipment to make waste gas and dust emissions meet or even exceed national and local environmental protection standards. For example, we are the first to launch low-emission spraying equipment, and the waste gas and dust emissions meet EU standards, which has won a good social reputation for the company.

- Establish a wastewater recycling treatment system to achieve "zero wastewater discharge", reduce water treatment costs, reduce water resource waste, conform to the trend of environmental protection development, and save costs for customers.

6. Good industry reputation and rich cases

- Provide spraying services with leading companies in the fields of new energy, auto parts, home appliances, etc. in the industry, and obtain high recognition from customers through excellent product quality and services, and witness strength with cases.

- Enhance the company's visibility and influence in the industry and establish a good brand image by participating in the formulation of industry standards, obtaining relevant qualification certifications, and participating in industry exhibitions

IMLUCKY Automatic Powder Coating Line for Water Heaters Hanging Coating Production Line High-temperature Curing Furnace

IMLUCKY Circular Tube Spraying Equipment Plastic Parts Hardware LED Light Strip Automatic Spraying Equipment

IMLUCKY Aluminum Powder Painting Machine Electrostatic Spray Powder Machine Paint Line for Metal Panel Surface Finishing

IMLUCKY Full Automatic Iron Railing Electrostatic Powder Coating Line for Spray Paint Aluminium Profile