Procesy malowania ręcznego napotykają na wrodzone ograniczenia ludzkich operatorów, które negatywnie wpływają na jakość powłoki. Zmęczenie operatora powoduje mierzalne pogorszenie się wyników – badania pokazują, że ręczne operacje natryskowe charakteryzują się o 78% wyższym poziomem wad niż systemy zautomatyzowane (Ponemon 2023). Maszyny do malowania automatycznego rozwiązują te problemy dzięki precyzji mechanicznej i stabilnemu, kontrolowanemu klimatycznie środowisku.

Wyzwania związane z malowaniem ręcznym: niestabilność i zmęczenie operatora

Operatorzy ludzkimi napotykają nieunikniony spadek sprawności fizycznej i psychicznej podczas długich zmian. Nawet wykwalifikowani operatorzy wykazują wahania ±15¼m w grubości powłoki w porównaniu do tolerancji ±5¼m osiąganej przez systemy robotyczne. Czynniki środowiskowe, takie jak wahania temperatury w komorze malarskiej, dodatkowo nasilają te niestabilności, prowadząc do wad na 12% powierzchni pokrywanych ręcznie w porównaniu do 3,8% w liniach zautomatyzowanych.

Jak maszyny malujące automatyczne zapewniają powtarzalne i jednolite nanoszenie

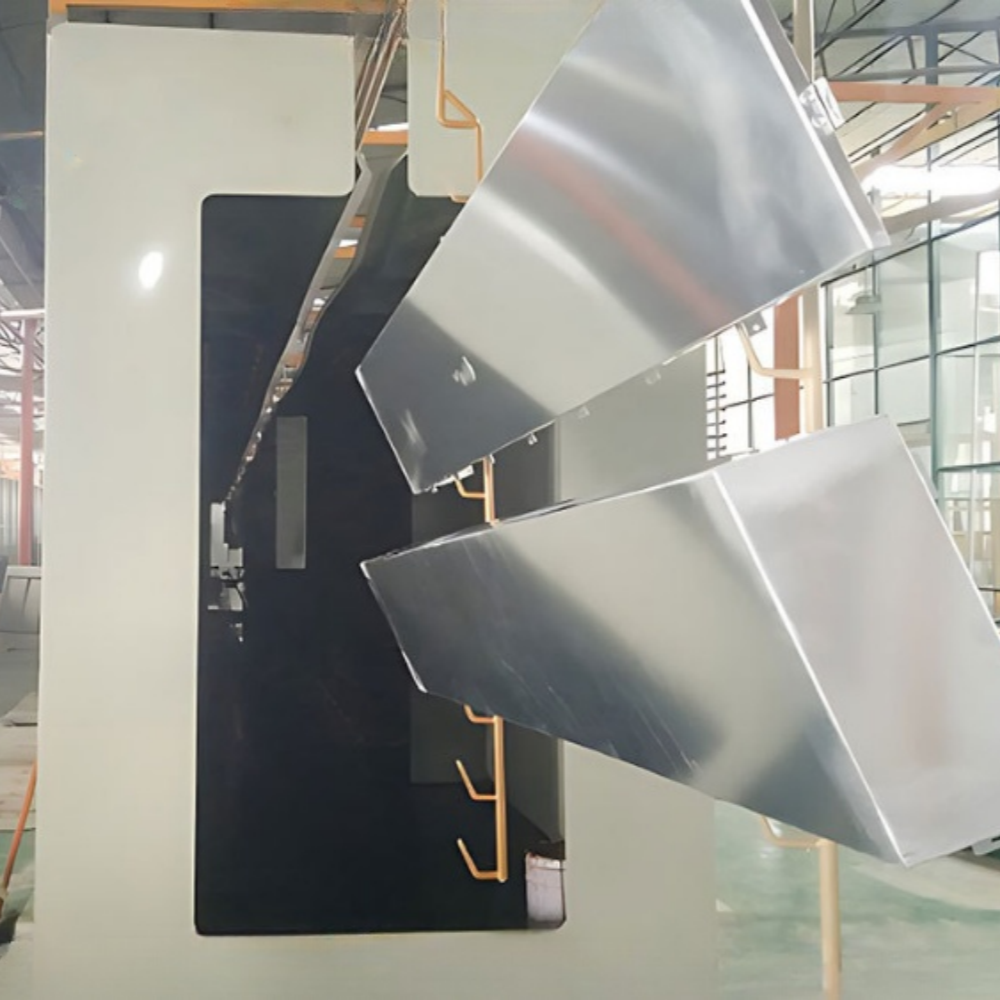

Linie do natrysku proszkowego wykorzystują serwonapędzony system taśmociągowy z optycznymi skanerami pozycjonującymi, aby utrzymać stałą tolerancję pozycjonowania wynoszącą 0,08 mm dla przedmiotów o różnych kształtach i rozmiarach. Wbudowane monitory ładunku elektrostatycznego ciągle kalibrują gęstość osadzania proszku, automatycznie kompensując takie czynniki jak geometria części i przewodność materiału, aby zapobiec nierównomiernemu nagromadzeniu powłoki. Raport z 2024 roku na temat produkcji wykazał, że linie tego typu osiągają 32% redukcję nadmiaru proszku w porównaniu z tradycyjnymi metodami, a także 99% jednolitość w serii produkcji.

Studium przypadku: Producent OEM samochodów zmniejsza wady powłok o 68% dzięki automatyzacji

Europejski producent pojazdów zastąpił stanowiska ręczne maszynami do malowania automatycznymi w trzech liniach produkcyjnych. Modernizacja wyeliminowała 42 000 rocznych godzin prac poprawkowych dzięki utrzymaniu stałych parametrów odległości i nakładania się dysz. Audyty jakości wykazały 68% redukcję śladów cieku i ściekających farb – wad, które wcześniej powodowały roczne koszty 1,2 mln USD w reklamacjach gwarancyjnych.

Precyzyjna kontrola jednolitej grubości powłoki w systemach robotycznych

Wpływ nierównomiernej grubości powłoki na jakość produktu

Nawet niewielkie odchylenia grubości powłoki (±5 µm) pogarszają odporność na korozję, integralność konstrukcyjną oraz jakość estetyczną. Badania automotive wykazały, że komponenty z nieregularnymi powłokami nie wytrzymują testu odpryskowego 22% krócej niż części prawidłowo pokryte farbą. Zbyt cienkie warstwy przyspieszają utlenianie metali, podczas gdy nadmierne nagromadzenie farby powoduje pękanie pod wpływem naprężeń termicznych.

Zaawansowana kontrola trajektorii i parametrów natrysku w maszynach do malowania automatycznego

Systemy robotyczne łączą czujniki IoT i sztuczną inteligencję, aby dynamicznie dostosowywać sześć kluczowych parametrów:

|

Parametr |

Ręczna tolerancja |

Automatyczne sterowanie |

|

Odległość rozpylania |

± 15 mm |

±0,5 mm |

|

Ciśnienie w dyszy |

±3,5 PSI |

±0,2 PSI |

|

Prędkość ramienia |

±12% |

±1.2% |

Algorytmy uczenia maszynowego przetwarzają 2000+ punktów danych na sekundę — od poziomu wilgotności po geometrię części — aby optymalizować ścieżki przy użyciu wielokryterialnych frameworków optymalizacyjnych. Ta precyzja zmniejsza odpady materiałowe o 33% w porównaniu do natrysku ręcznego.

Studium przypadku: Producent lotniczy osiąga tolerancję powłoki ±2 µm

Producent łopatek turbinowych wdrożył systemy robotyczne do malowania z adaptacyjnym pomiarem grubości. Po zoptymalizowaniu trajektorii dla wklęsłych powierzchni profili aerodynamicznych osiągnięto jednolitość powłoki na poziomie 98,7% wśród 12 000 komponentów. Wady wymagające przeróbki spadły z 14% do 2,1% rocznie — co odpowiada oszczędnościom w wysokości 740 000 USD (Ponemon 2023). Ich sukces odzwierciedla przełomy w motoryzacji opisane w badaniach branżowych, co dowodzi zastosowania w różnych sektorach.

Zmniejszanie wad i przeróbek dzięki zautomatyzowanym procesom powlekania

Typowe wady powłok w systemach ręcznych: ścieki, przewisy i rozpylone farby

Wykończenia nanoszone ręcznie po prostu nie są tak jednorodne, jak się wydaje. Operatorzy mają trudności z utrzymaniem pistoletu malarskiego pod właściwym kątem, poruszaniem się z odpowiednią prędkością i utrzymywaniem właściwej odległości od malowanego elementu przez cały czas pracy. Efektem są ścieki powstające tam, gdzie w jednym miejscu gromadzi się zbyt dużo farby, przewisy powodujące nieestetyczne krople ściekające po pionowych powierzchniach oraz spora ilość marnowanego materiału, który rozpryskuje się w powietrzu zamiast trafić na właściwą powierzchnię. Zgodnie z najnowszymi badaniami przemysłowymi przeprowadzonymi przez Finishing Trends (2024), około 35 procent całej ilości używanej powłoki traci się wyłącznie z powodu tego zjawiska zwanego overspray. A kiedy farba nie jest równomiernie nanoszona na elementy, fabryki muszą przerabiać około 18 procent swoich powłok, co negatywnie wpływa na czas i koszty produkcji.

Monitorowanie w czasie rzeczywistym i sprzężenie zwrotne w systemach malowania robotycznego

Maszyny do automatycznego malowania eliminują te niejednorodności dzięki systemom sterowania w pętli zamkniętej. Zintegrowane czujniki mierzą zmienne takie jak lepkość, temperatura i przewodność powierzchniowa, a systemy wizyjne monitorują w czasie rzeczywistym grubość powłoki. W przypadku wystąpienia odchyleń system natychmiast dokonuje korekty:

- Odległość dyszy natryskowej zmniejsza się o 0,2—1,5 mm, aby zapobiec zbieganiu farby

- Ciśnienie atomizacji zwiększa się o 8—12 psi, aby zminimalizować rozpylanie

- Prędkość trajektorii robota zmienia się o ±15%, aby zapewnić równomierne pokrycie

Najnowze postępy w zakresie automatycznego wykańczania wykazują, że linie zrobotyzowane osiągają wskaźnik jakości pierwszego przejścia na poziomie 99,4%, korelując 1200+ parametrów procesowych z wzorcami wad przy użyciu uczenia maszynowego.

Studium przypadku: Producent sprzętu AGD obniżył koszty przeróbek o 45%

Jeden z dużych producentów urządzeń AGD zredukował nakłady związane z poprawkami malarskimi, które wcześniej kosztowały ich około 280 tys. dolarów rocznie, obniżając te wydatki do zaledwie 126 tys. dolarów po zainstalowaniu nowego systemu malowania automatycznego. Kluczowe znaczenie miały czujniki podczerwieni wykorzystywane w procesie suszenia, które wykrywały problemy z niepełnym utwardzeniem w około 12% produktów – czego nikt wcześniej nie zauważał podczas standardowych wizualnych kontroli. System automatycznie dostosowywał wówczas temperaturę pieców i regulował prędkość przemieszczania się elementów wzdłuż linii produkcyjnej. Pozwoliło to nie tylko wyeliminować dokuczliwe problemy związane z pęcherzami i łuszczzeniem farby, ale również zaoszczędzić 22% kosztów energii, zgodnie z opublikowanymi w zeszłym roku benchmarkami branżowymi.

Integrowanie zaawansowanych technologii dla inteligentniejszego i bardziej spójnego pokrywania powierzchni

Integracja IoT i czujników w inteligentnych kabinach malarskich

Współczesne zautomatyzowane urządzenia malarskie wykorzystują czujniki podłączone do internetu, aby monitorować istotne czynniki środowiskowe podczas pracy. Mówimy tutaj o takich parametrach jak poziom wilgotności między 60 a 80 procent wilgotności względnej, temperatury na poziomie 20 do 25 stopni Celsjusza oraz prędkości przepływu powietrza wynoszącej około 0,3 do 0,5 metra na sekundę. Inteligentne kabiny malarskie samodzielnie dokonują odpowiednich korekt, aby utrzymać te warunki w optymalnym zakresie sprzyjającym prawidłowej adhezji farby. Zgodnie z wynikami analizy branżowej opublikowanej w zeszłym roku, producenci stosujący te połączone systemy mogą spodziewać się obniżenia poziomu marnotrawstwa materiałów o około dwadzieścia dwa procent. W tym samym czasie należy oczekiwać poprawy wynoszącej około osiemnaście procent w uzyskiwaniu poprawnych rezultatów już za pierwszym razem, zamiast konieczności powtarzania prac. Tego rodzaju ulepszenia przynoszą teraz realne różnice w wielu operacjach związanych z przemysłowym nanoszeniem powłok.

AI i uczenie maszynowe w predykcyjnej kontroli jakości

Analizując wcześniejsze zapisy dotyczące powłok, systemy uczenia maszynowego mogą wykrywać problemy zanim się pojawią, zapobiegając wadom takim jak struktura pomarańczowej skórki czy suche plamy na powierzchniach. Ostatnie badania wykazały również imponujące wyniki – około 94% skuteczności w dopasowaniu odczytów podczerwieni do późniejszej twardości powłoki. Co to oznacza dla produkcji? Roboty malarskie mogą teraz niemal natychmiast dostosować swoje ustawienia, jeśli coś wyjdzie z normy. Pistolety natryskowe przemieszczają się bliżej lub dalej, a zmiana ciśnienia następuje w ciągu zaledwie pół sekundy od momentu wykrycia przez system nieprawidłowości w procesie.

Trendy przyszłości: Samo-optymalizujące się systemy powłokowe z pętlami sprzężenia zwrotnego automatyki

Nowa fala systemów produkcyjnych łączy technologię wizji 3D z mechanizmami kontroli w pętli zamkniętej, tak aby roboty mogły dynamicznie dostosowywać swoje ścieżki ruchu. Niektóre wczesne modele testowe już teraz prezentują imponujące wyniki w wykrywaniu krawędzi z dokładnością do około 0,02 milimetra, co oznacza, że mogą one automatycznie korygować sytuację, gdy części nie są dokładnie prawidłowo ustawione. W przyszłości eksperci szacują, że te inteligentne platformy mogą osiągnąć niemal 99,6-procentową jednolitość powłok nawet na skomplikowanych kształtach do końca dekady. Jednocześnie istnieje potencjał do obniżenia zużycia energii na jednostkę produktu o około 31 procent, choć rzeczywista wydajność będzie zależała od tego, jak dobrze producenci wdrożą te technologie w warunkach rzeczywistych.

Często zadawane pytania

Jakie są główne korzyści wynikające z zastosowania maszyn do automatycznego malowania w porównaniu do procesów ręcznych?

Maszyny do malowania automatycznego zapewniają wyższą precyzję i spójność, znacznie zmniejszając liczbę wad i koszty przeróbek w porównaniu z malowaniem ręcznym. Minimalizują również odpady materiałowe i gwarantują jednolitą grubość powłoki, co poprawia działanie produktu.

W jaki sposób systemy robotyczne kontrolują spójność nanoszenia farby?

Systemy robotyczne wykorzystują czujniki i sztuczną inteligencję do dynamicznego dostosowywania parametrów takich jak odległość natrysku, ciśnienie w dyszy i prędkość ramienia, zapewniając spójne i jednolite nanoszenie farby na powierzchniach.

Czy systemy zautomatyzowane mogą być stosowane w innych branżach niż motoryzacyjna?

Tak, systemy malowania automatycznego mogą być stosowane w różnych branżach, w tym lotniczej i AGD, co potwierdzają studium przypadków pokazujące znaczące poprawy jednolitości powłoki i zmniejszenie liczby wad.

W jaki sposób systemy automatyczne utrzymują efektywność w różnych warunkach środowiskowych?

Systemy automatyczne są wyposażone w czujniki IoT, które monitorują i dostosowują warunki środowiskowe, takie jak wilgotność i temperatura, w celu zapewnienia optymalnego przylegania i spójności farby, skutecznie adaptując się do różnych środowisk.

Jakie nowości można spodziewać się w przyszłości na rynku maszyn do automatycznego malowania?

W przyszłości należy spodziewać się rozwoju systemów samooptymalizujących się z zaawansowaną integracją czujników, technologii wizji 3D oraz poprawy efektywności energetycznej, stopniowo zmierzając do niemal idealnej jednolitości powłoki i obniżki kosztów operacyjnych.

Spis treści

- Wyzwania związane z malowaniem ręcznym: niestabilność i zmęczenie operatora

- Jak maszyny malujące automatyczne zapewniają powtarzalne i jednolite nanoszenie

- Studium przypadku: Producent OEM samochodów zmniejsza wady powłok o 68% dzięki automatyzacji

- Precyzyjna kontrola jednolitej grubości powłoki w systemach robotycznych

- Zmniejszanie wad i przeróbek dzięki zautomatyzowanym procesom powlekania

- Integrowanie zaawansowanych technologii dla inteligentniejszego i bardziej spójnego pokrywania powierzchni

- Integracja IoT i czujników w inteligentnych kabinach malarskich

- AI i uczenie maszynowe w predykcyjnej kontroli jakości

- Trendy przyszłości: Samo-optymalizujące się systemy powłokowe z pętlami sprzężenia zwrotnego automatyki

-

Często zadawane pytania

- Jakie są główne korzyści wynikające z zastosowania maszyn do automatycznego malowania w porównaniu do procesów ręcznych?

- W jaki sposób systemy robotyczne kontrolują spójność nanoszenia farby?

- Czy systemy zautomatyzowane mogą być stosowane w innych branżach niż motoryzacyjna?

- W jaki sposób systemy automatyczne utrzymują efektywność w różnych warunkach środowiskowych?

- Jakie nowości można spodziewać się w przyszłości na rynku maszyn do automatycznego malowania?