Auto parts spraying

Auto parts, including engines, chassis, and body accessories, have diverse functions. Spray coatings serve three purposes: first, they isolate parts from media like water, oil, and air, providing protection against rust, corrosion, and oil. Second, through special treatments like damping coatings, they impart shock absorption, sound absorption, and heat insulation. Third, they optimize the appearance and texture, satisfying decorative requirements like color and gloss. Quality control is strictly enforced to prevent appearance defects and ensure that coating thickness, hardness, and environmental resistance meet standards to meet vehicle operating requirements.

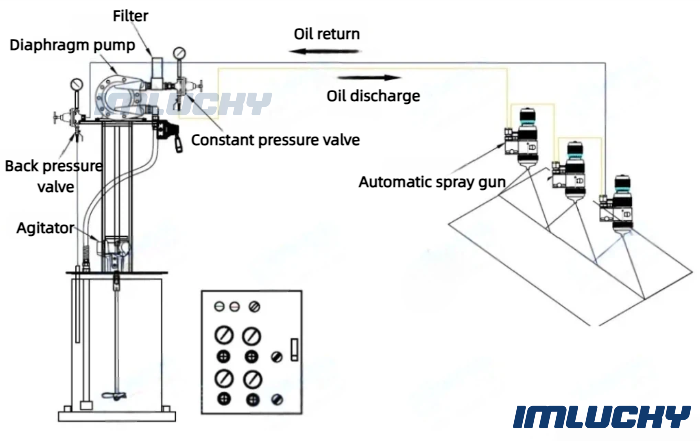

The spraying process includes pre-treatment, coating, and curing. Pre-treatment ensures the adhesion of the coating, and the automotive parts are sprayed through spraying equipment to form functional and decorative coatings on the surface.

When spraying auto parts, using paint with low volatile organic compound (VOC) content, spraying equipment with environmentally friendly atomization technology and precise paint control technology can improve paint utilization and operating efficiency, reduce paint mist dispersion, reduce waste generation, reduce resource consumption, and reduce waste pollution to the environment.

Spraying case description

This application case involves spray coating automotive parts.

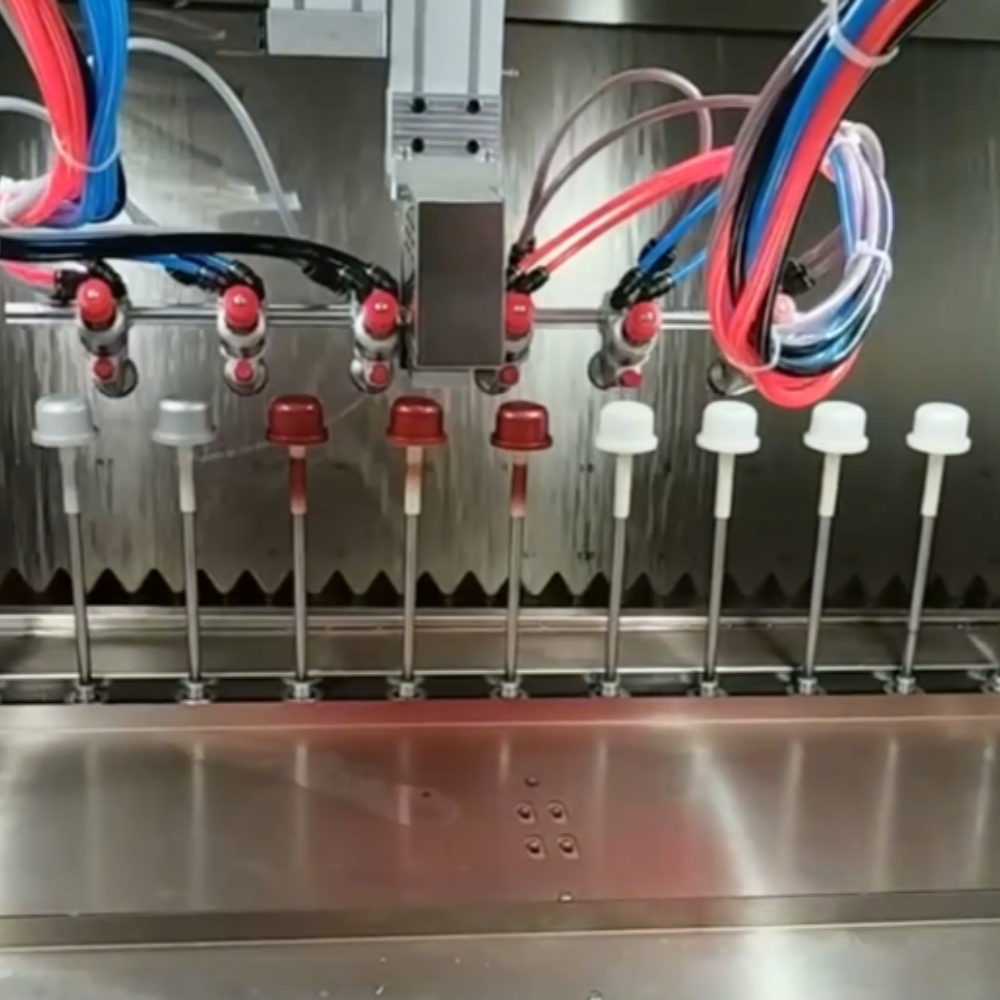

The automated production line equipped with automatic spray guns enables high-volume application, resulting in fast and uniform coating. This reduces paint waste and rework, while also alleviating environmental pressures, increasing production capacity, and optimizing coating costs to achieve excellent coating quality and exceptionally high efficiency.

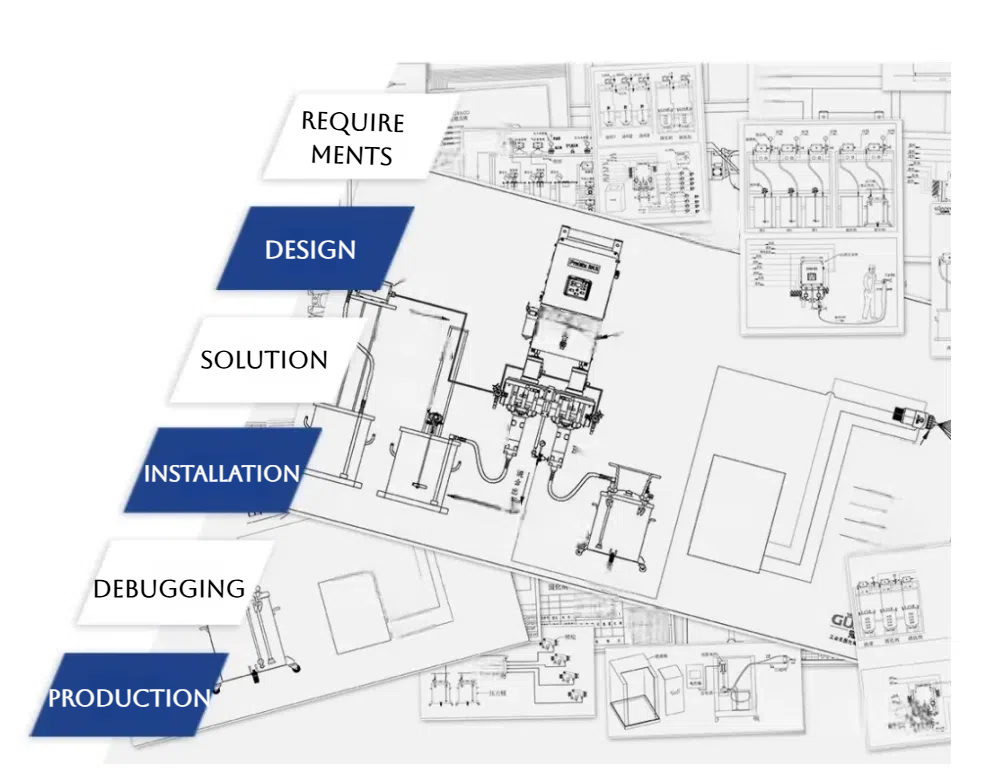

Based on our customers' spray painting needs, IMLUCKY's professional technicians can customize a complete solution.

Product Details:

GRACO AirPro EFX automatic spray gun (USA)

Timmer pneumatic diaphragm pump (Germany)

Paint pressure regulator

Paint hose

Air hose

Pneumatic agitator

Integrated feed rack

Automatic spray gun with intelligent spray control

Use the Graco AirPro EFX automatic spray gun for stable paint delivery paired with a Timmer 1060 pneumatic diaphragm pump for spraying automotive parts.

Spraying produces a uniform, smooth, durable, and paint-saving coating, effectively saving material costs and complying with environmental regulations. Automated spraying significantly increases productivity and allows for the rapid production of high-quality products. Suitable for a variety of spray applications, it meets your spraying needs!

Air spray uses a low-pressure fluid to atomize the material under controlled conditions. The low-pressure fluid stream mixes with compressed air at the air cap. This technology is suitable for spraying low- to medium-viscosity fluids for products requiring high-quality finishes (Class A or decorative finishes).

Due to evolving environmental regulations, IMLUCKY has developed different versions of air spray technology:

● Conventional is the traditional form of air spray technology, offering the highest quality and fastest production speeds. To achieve these advantages, large volumes of air are used, resulting in lower transfer efficiency.

● High Volume, Low Pressure (HVLP) was developed specifically for EPA-regulated areas. To meet these regulations, the air volume used at the air cap is limited to 10 psi. Results show that this low-speed mode offers better spray quality and higher transfer efficiency than conventional methods.

● Compliant technology, typically referred to as Low Flow Medium Pressure (LVMP), was developed specifically to meet European standards. It requires an inlet pressure of no more than 29 psi. This allows for an air cap design that delivers high-quality spraying with transfer efficiencies equal to or better than HVLP.

We provide customized spray solutions and comprehensive support for automotive parts manufacturers, encompassing a complete range of equipment from spray pumps and metering systems to spray guns.

Whether you require single or double component materials, with varying flow rates and viscosities, we can meet your spraying needs.

IMLUCKY

A professional spray equipment service provider, dedicated to serving you.

We can provide you with

Customized configurations to meet your individual needs.

Online or in-person installation training available.

Technical Support

Where the coating industry is, IMLUCKY is everywhere.

IMLUCKY has been specializing in the spray coating industry in China for over 15 years, always adhering to a clear goal: to help the manufacturing industry achieve energy conservation, efficiency, and environmental protection.

As a factory specializing in spray coating technology for over 15 years, IMLUCKY is committed to providing world-leading industrial products, coating technologies, and services to a wide range of industries. Our professional team can provide you with everything from simple spray tools to complex automated and intelligent customized solutions.