Construction Machinery Manufacturing Construction machinery structural components (such as excavator booms/sticks, loader frames, crane booms, etc.) are the "skeleton" of the equipment. They are constantly exposed to outdoor dust, mud, industrial atmospheres, and mechanical vibrations. During use, they often face various corrosive environments, including atmospheric corrosion, soil corrosion, and corrosion from chemical media. Anti-corrosion spraying must simultaneously meet three core requirements: weather resistance, wear resistance, and vibration resistance.

Anti-corrosion spraying forms a continuous, dense protective layer on the surface of the structural components, effectively isolating them from corrosive media and preventing corrosion, thus significantly extending the service life of the construction machinery structural components. The painting process typically follows strict operating procedures and safety standards to ensure construction quality and environmental safety.

IMLUCKY offers a wide variety of products and different spraying technologies for your selection! Through spray coating, you can effectively prevent rust and corrosion from damaging the surface of engineering machinery structural components, improving durability and protective performance.

Furthermore, modern spraying emphasizes environmental protection, using paints with low volatile organic compound (VOC) content, employing paint-saving spraying equipment and precise paint control technology. This improves paint utilization and operational efficiency, reduces paint mist dispersion, reduces waste generation, reduces resource consumption, and minimizes environmental pollution from waste.

Spray Coating Case Study

This application case demonstrates a client's spray coating process for structural components in engineering machinery. After spraying with a reciprocating robotic arm, manual touch-ups are performed to improve manufacturing efficiency, reduce defect rates, and minimize rework. The use of a high-pressure airless spraying robotic arm and a high-pressure airless manual spray gun ensures stable paint delivery, saving paint and promoting environmental friendliness. It can handle high-viscosity and solvent-free materials, and with the addition of a heater, the paint film surface is more uniform, resulting in excellent coating quality and extremely high coating efficiency.

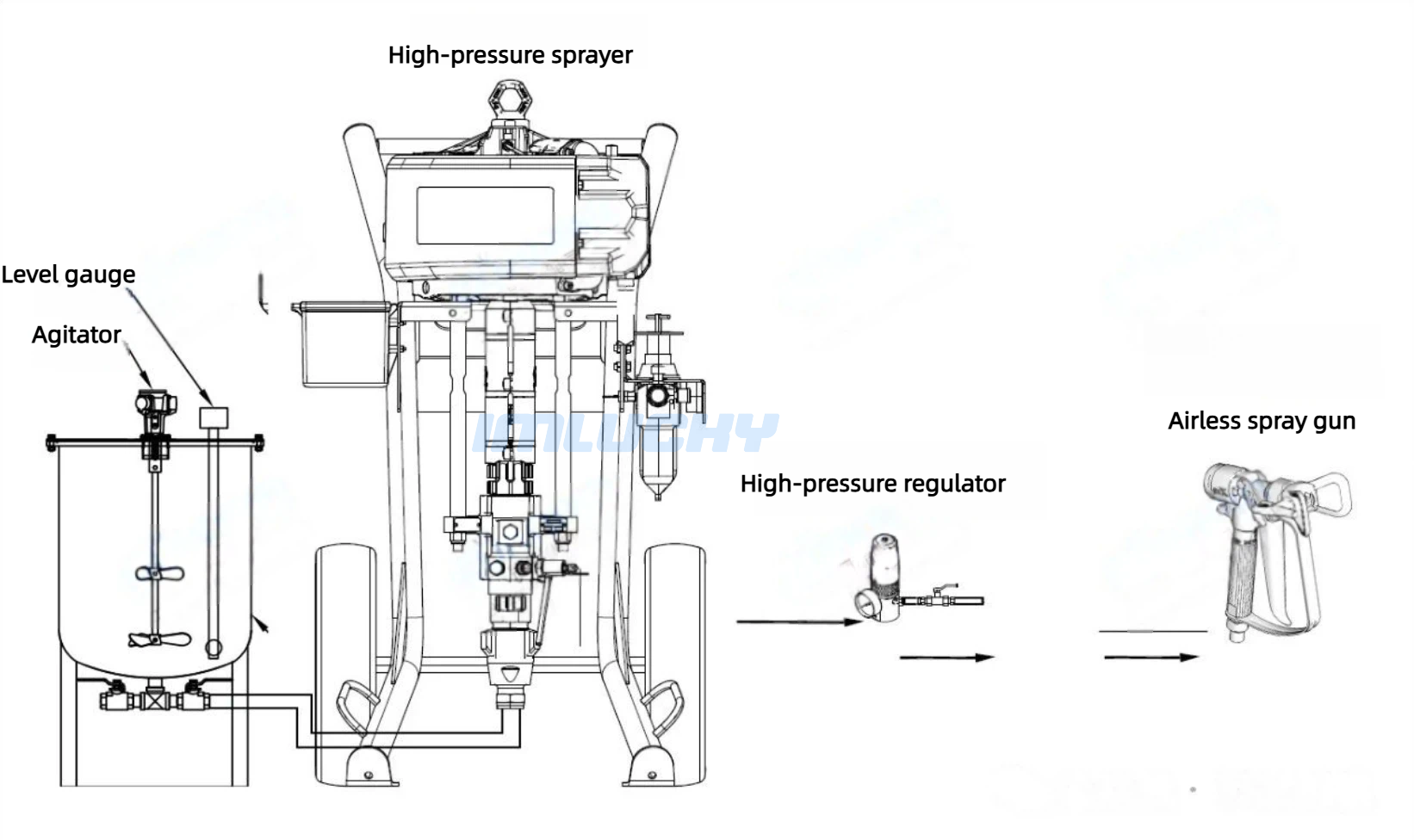

Based on the client's spray coating needs, IMLUCKY's professional engineers customize a complete solution to meet their requirements. Product Configuration Details: Graco King Airless Sprayer (USA), Graco XTR+ Airless Spray Gun (USA), Paint Delivery Tank, Tank Lid Agitator, Graco Heater (USA), High-Pressure Hose, Pump Inlet Pressure Regulator

A good anti-corrosion coating should possess the following characteristics: • Excellent adhesion, ensuring long-term coating durability • Good chemical corrosion resistance • High mechanical strength and abrasion resistance • Weather resistance, adaptable to various climatic conditions

*Note: Airless spraying uses high-pressure fluid for atomization, without compressed air, relying solely on fluid pressure. It generates airflow by hydraulically propelling the material through the nozzle. As the fluid leaves the orifice, friction between the fluid flow and the atmosphere breaks it down into smaller particles. Nozzle size and pressure determine the material flow rate. This technology is suitable for medium to high viscosity fluids, resulting in lower spray quality, but it is ideal for applications requiring higher speed and delivery efficiency.

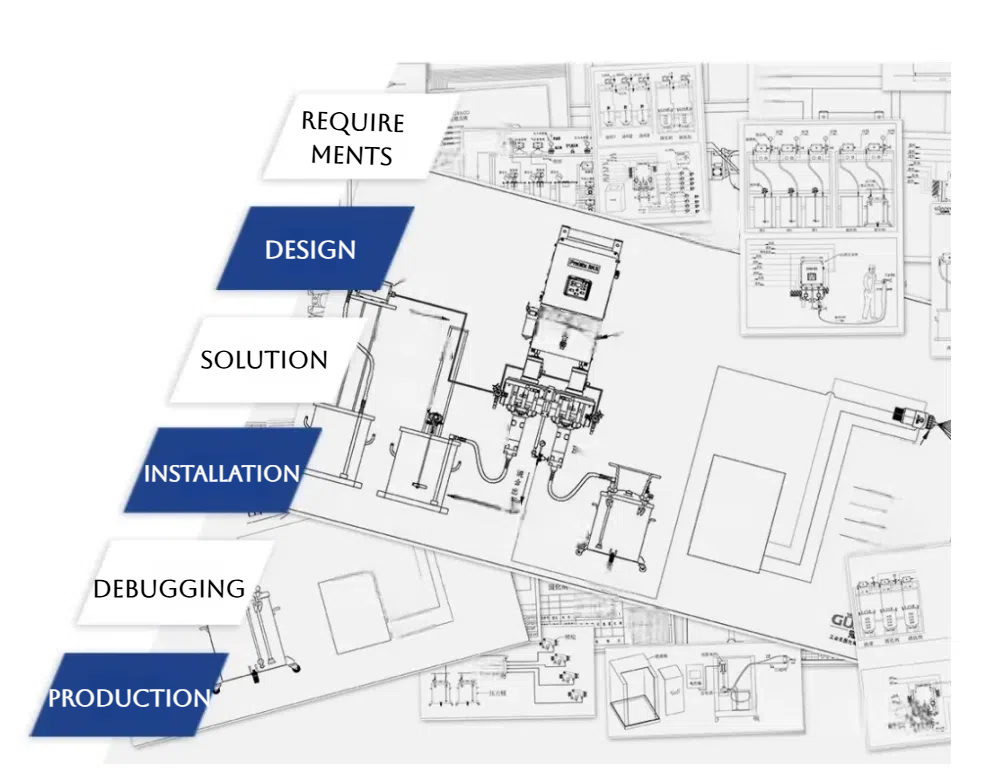

We provide customized spraying solutions and full support for engineering machinery structural components, covering a complete set of equipment from spray pumps and metering systems to spray guns. Whether you need single-component or two-component materials, regardless of flow rate or viscosity variation, we can meet your spraying needs.

IMLUCKY

A professional spray painting equipment service provider, dedicated to serving you wholeheartedly.

We can provide you with...

Customized configurations to meet your individual needs. Supports online guidance and offline installation training. Technical support.

Where painting is needed, IMLUCKY is everywhere. IMLUCKY has focused on the spray painting field in China for over 15 years, always adhering to a clear goal: to help the manufacturing industry achieve energy conservation, efficiency, and environmental protection.

As a factory specializing in spray painting technology for over 15 years, IMLUCKY is committed to providing world-leading industrial products, coating technologies, and services to various industries. Our professional team can provide you with everything from simple spray painting tools to complex automated and intelligent customized solutions.