Provide solutions according to customer requirements

Production within 45-90 days, 100% on-time delivery rate

Delivery and professional door-to-door installation

12-month warranty on core accessories

Fully automatic electrostatic powder coating line, equipped with integrated automatic conveying system, can work continuously under the program of electronic control system. Ensure efficient and energy-saving operation.

The efficient recovery system increases the powder utilization to the limit and reduces costs.

1.coating process

Electrophoretic coating is a coating process that uses an applied electric field to direct the migration of pigments and resin particles suspended in an electrophoretic fluid and deposit them on the workpiece surface. Compared to traditional spray coating methods such as painting and dipping, it offers stronger adhesion, is more environmentally friendly, and offers enhanced corrosion resistance.

2.principle

Firstly, the electrophoretic coating process involves both physical and chemical reactions, resulting in stronger adhesion. Furthermore, water-based electrophoretic fluids contain no volatile organic compounds (VOCs), and the wastewater can be recycled after treatment. This not only reduces environmental treatment costs for businesses, but also reduces water and coating costs – effectively killing two birds with one stone. Electrophoretic coating forms a continuous film that effectively isolates water, oxygen, and corrosive media. It can withstand salt spray tests for hundreds of hours, surpassing traditional spray coating and offering even greater corrosion resistance.

3.Advantages

Due to its high efficiency and environmental friendliness, electrophoretic coating has been widely used in automotive, home appliance, building materials, medical device, and other fields, becoming a highly competitive option in industrial coatings.

Pretreatment (Core: Impurity Removal and Surface Activation)

Pretreatment directly impacts the adhesion and corrosion resistance of the electrophoretic coating and is a critical step:

1. Pre-cleaning

- Remove oil (such as machine oil, anti-rust oil), rust, scale, dust, and other contaminants from the workpiece surface.

- Methods: Manual wiping (for small parts), high-pressure water jet washing, shot blasting/sandblasting (for thick rust or scale).

2. Degreasing

- Use an alkaline solution (such as sodium hydroxide, sodium carbonate) or a dedicated degreaser through immersion, spraying, or ultrasonic cleaning to thoroughly remove oil contaminants.

- Purpose: Prevent oil contaminants from interfering with the subsequent phosphate film formation and electrophoretic coating adhesion.

3. Water Rinse

- Rinse any remaining degreaser from the workpiece surface with running water to prevent acid and alkali residues from affecting subsequent processes.

- Typically performed in one or two steps to ensure no residual degreasing agent is present.

4. Rust Removal (for rusted workpieces)

- Soak or spray with an acidic solution (such as hydrochloric acid or sulfuric acid) to dissolve rust.

- Control the time to avoid excessive corrosion of the workpiece substrate.

5. Surface Conditioning

- Treat the workpiece surface with a weak acid or colloidal solution (such as a titanium salt) to make the subsequent phosphate film finer and more uniform.

- Primarily for steel parts, this treatment improves phosphate coating quality.

6. Phosphating

- Immerse the workpiece in a phosphating solution (containing phosphates such as zinc, manganese, and iron), forming a uniform phosphate film (typically 1-5μm thick) on the surface.

- Function: Enhances adhesion between the workpiece and the electrophoretic coating and improves corrosion resistance.

7. Pure Water Rinse

- Rinse with deionized or purified water to remove residual phosphating agents and impurities, preventing any impact on the stability of the electrophoretic solution.

- Typically, two to three coats are performed, with the final coat ensuring the workpiece surface conductivity is ≤50μS/cm.

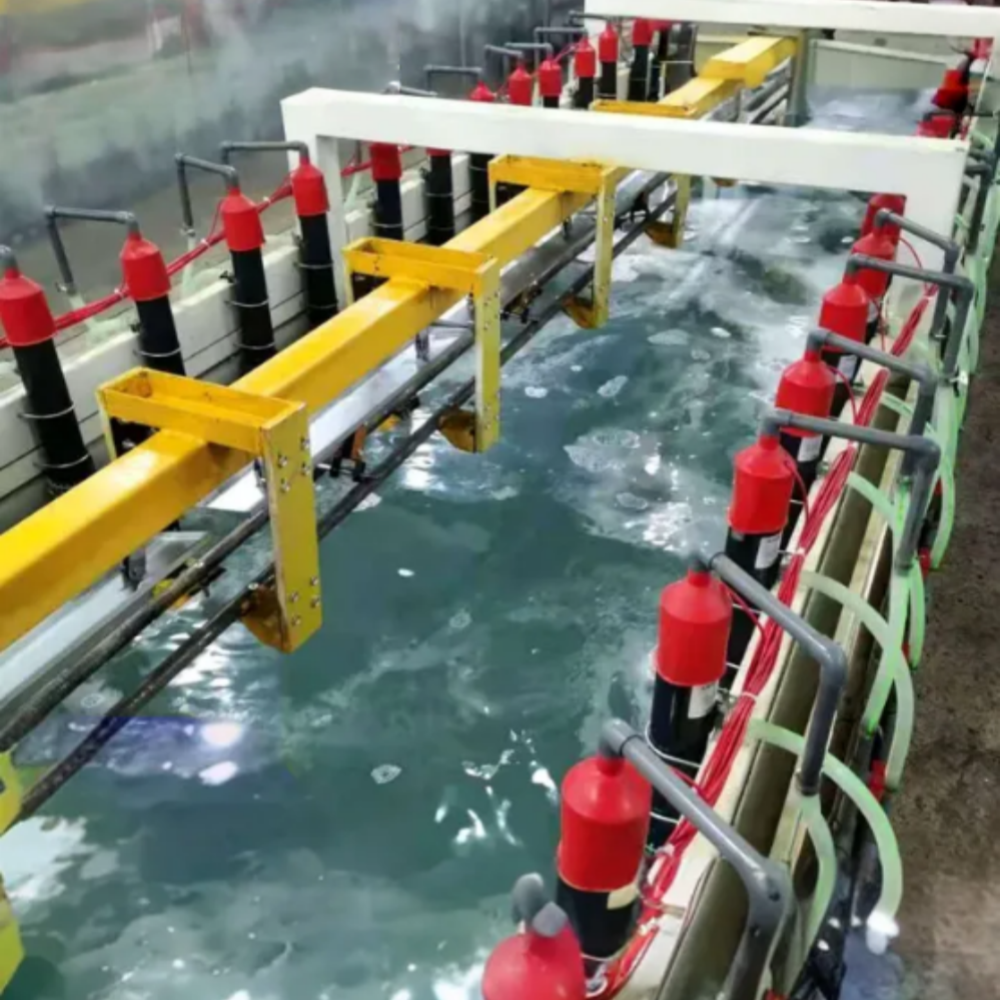

II. Electrophoretic Coating (Core: Coating Deposition Under Electric Field)

1. Workpiece Placement

- After pre-treatment, hang the workpiece on a dedicated hanger to ensure good conductivity and immerse it in the electrophoretic bath (which contains a water-based electrophoretic paint solution containing resin, pigment, additives, etc., with adjusted pH and solids content).

2. Electrophoresis

- Connect the workpiece to an electrode (the workpiece serves as the cathode in cathodic electrophoresis and the anode in anodic electrophoresis), and the bath or a dedicated plate to the opposite electrode. Apply a DC voltage (usually 50-300V).

- Under the influence of the electric field, the charged paint particles in the electrophoretic bath migrate toward the workpiece. Upon reaching the surface, the charge is neutralized and deposited, forming a wet film.

- Control parameters: voltage, electrophoresis time (usually 1-5 minutes), and paint bath temperature (20-30°C) to ensure a uniform film thickness (usually 10-30μm). 3. Workpiece Removal

- After power is turned off, the workpiece is removed from the electrophoretic coating tank. Uncured wet coating and residual paint remain on the surface.

III. Post-Processing (Core: Curing the Coating and Improving Performance)

1. Ultrafiltration Wash (UF Wash)

- The workpiece surface is rinsed with electrophoretic coating liquid (which is impurity-free and has a low solute concentration) filtered through an ultrafiltration device. This rinse recovers residual paint (increasing coating utilization) and reduces the burden of subsequent pure water washes.

- Typically, one or two coats are used to remove most loose paint.

2. Pure Water Wash

- Rinse with deionized water to thoroughly remove residual paint and salt from the workpiece surface, preventing defects such as craters and pinholes after drying.

3. Drying and Curing

- The workpiece is placed in a drying oven and baked at high temperature (usually 160-180°C for cathodic electrophoretic coating, slightly lower for anodic electrophoretic coating) for 20-30 minutes.

- The moisture in the wet coating evaporates, and the resin undergoes a cross-linking reaction (chemical reaction), forming a dense, hard, cured coating.

4. Cooling and Inspection

- After exiting the furnace, the workpiece is cooled naturally or forcefully. The coating thickness, adhesion, and appearance (for pinholes, bubbles, and sags, etc.) are then inspected. Only qualified parts proceed to the next step (such as assembly or topcoat application).

The entire process is highly automated (e.g., bath parameters, temperature, and time), with each step seamlessly integrated, ultimately achieving efficient, high-quality coating results. This process is widely used in the automotive, home appliance, and hardware industries.

Electrophoretic coating is a coating process that uses an applied electric field to cause pigment and resin particles suspended in an electrophoretic fluid to migrate and deposit on the workpiece surface. Compared to traditional coating methods (such as spray painting and dipping), it offers the following significant advantages:

1. Excellent coating uniformity and adhesion

High uniformity: During the electrophoretic coating process, the electric field allows the paint particles to penetrate complex structural features such as crevices, grooves, and blind holes on the workpiece, achieving a comprehensive, seamless coating. This avoids the problems of exposed corners and uneven coating thickness associated with traditional spray coating, making it particularly suitable for workpieces with complex shapes (such as automotive parts and hardware).

-Strong adhesion: The coating adheres tightly to the workpiece surface, with adhesion indicators (such as the cross-cut test) far exceeding those of traditional coatings. It is less susceptible to flaking and peeling, significantly improving the corrosion resistance and service life of the workpiece.

2. High paint utilization rate and environmental friendliness

Utilization rate exceeds 95%: Paint particles in the electrophoretic fluid are deposited in a targeted manner through an electric field, and undeposited paint can be recycled, resulting in virtually no waste. Traditional spray coating, by contrast, only achieves a 30%-50% paint utilization rate, with a significant amount of paint discharged in exhaust gas or wastewater.

Significant environmental advantages: During the electrophoretic coating process, solvent volatilization is extremely low (water-based electrophoretic fluids contain no volatile organic compounds (VOCs)), reducing air pollution. Wastewater can be recycled after treatment, complying with environmental regulations and reducing environmental treatment costs for businesses.

3. High production efficiency, suitable for large-scale production

High degree of automation: Electrophoretic coating allows for fully automated production lines, requiring minimal human intervention throughout the entire process, from workpiece pre-treatment, electrophoresis, cleaning, to drying. This process is stable and efficient.

Fast coating speed: Single batches are quickly coated (typically several to ten minutes), and continuous production is possible, making it suitable for coating large quantities of workpieces and significantly increasing business production capacity.

4. Comprehensive Coating Performance, Outstanding Protection

Strong Corrosion Resistance: Electrophoretic coatings (especially cathodic electrophoretic coatings) form a continuous film that effectively isolates water, oxygen, and corrosive media. They can withstand salt spray tests for hundreds of hours (for example, electrophoretic coatings on automotive bodies often exceed 1,000 hours in salt spray tests), far exceeding traditional spray coatings.

Excellent Physical and Chemical Properties: The coating is hard, impact-resistant, and abrasion-resistant, with excellent weather resistance and decorative properties. It can be used directly as a primer or combined with a topcoat to enhance the overall coating effect.

5. Controllable Costs, High Overall Benefits

Low Long-Term Costs: While electrophoretic equipment requires a high initial investment, its high paint utilization rate, low energy consumption (compared to traditional high-temperature drying), and reduced labor costs make the overall cost significantly lower than traditional coatings over the long term.

Excellent Quality Stability: The electrophoretic process is precisely controlled by parameters (such as voltage, temperature, and time), resulting in minimal fluctuation in coating quality. This reduces defective products due to manual operation variability and reduces rework costs.

In summary, electrophoretic coating has been widely used in the fields of automobiles, home appliances, building materials, medical devices, etc. due to its high efficiency, environmental protection, and high quality, becoming a highly competitive process choice in industrial coating.

IMLUCKY Automatic Gantry Electrophoresis Equipment for Automobile Shell Stainless Steel Frame Powder Coating System

IMLUCKY Spot Intelligent Spraying Equipment Rail Suspended Powder Spraying Production Line

IMLUCKY Flat Metal Switch Box Automatic Paint Spraying Machine, Plastic Panel Automatic Reciprocating Spraying

IMLUCKY Automated Powder Recycling Equipment for Plastic Spraying Pre-treatment Spray Booths Machine