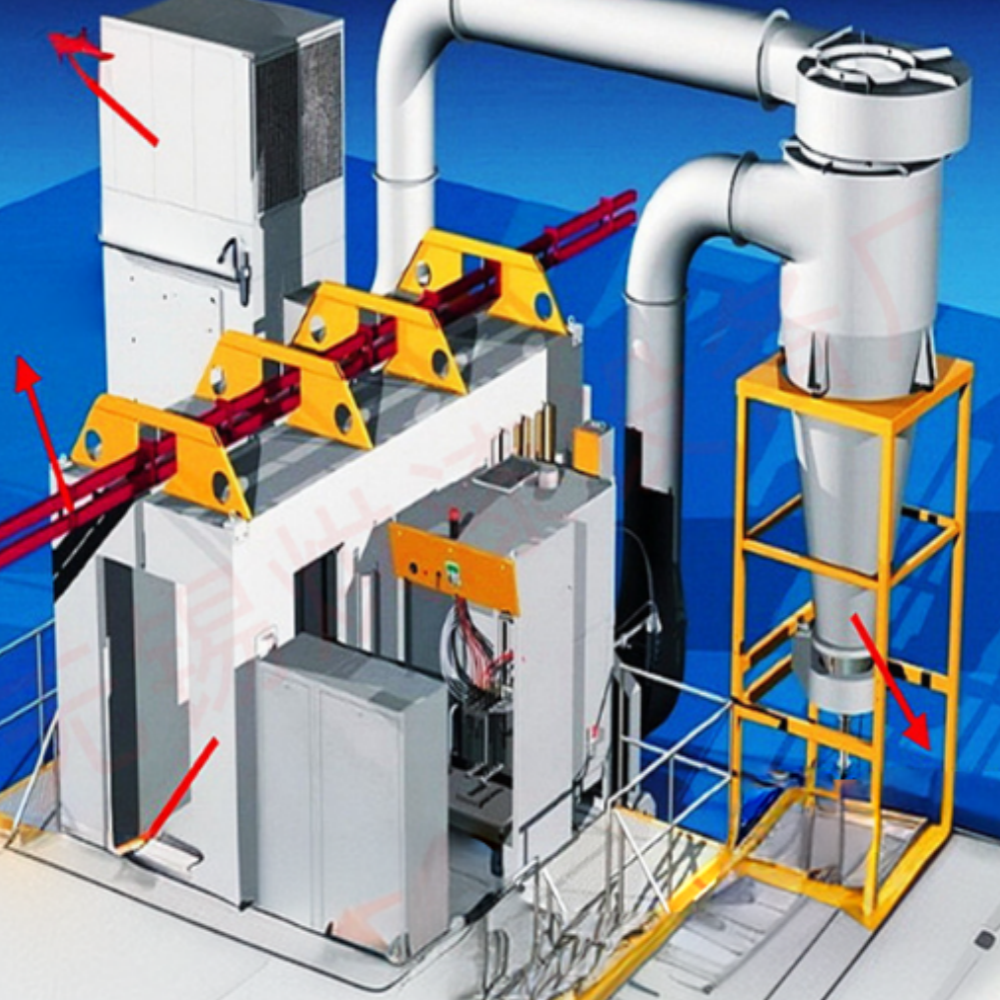

The IMLUCKY Automated Powder Recycling Equipment is designed to optimize efficiency in plastic spraying pre-treatment processes. This advanced spray booth machine features an integrated recycling system that captures and reuses excess powder, significantly reducing waste and operational costs. Engineered for seamless integration into existing production lines, it ensures consistent and high-quality coatings. The equipment's automated controls and user-friendly interface make it easy to operate, while its robust construction promises durability and long-term reliability. Ideal for manufacturers aiming to enhance sustainability and productivity in their coating operations.

The advantages of a powder recovery system are significant. First, it significantly improves material utilization, with powder recovery rates exceeding 98%, directly reducing raw material consumption.

Second, it aligns with green manufacturing principles. Through near-complete powder collection, it avoids waste emissions, protecting the environment and safeguarding the health of operators.

Finally, it achieves cost reduction and efficiency gains, not only saving on expensive coating costs and reducing waste disposal expenses, but also ensuring efficient and stable production processes through its automated, continuous operation.

As a result, this system has become a key indicator of the advancement of powder coating lines and is widely used in numerous industries, including automotive, home appliance, and building materials.

1. Economical:

The core of cost control, a key factor in profitability: Powder coatings are inherently expensive. Without a recovery system, oversprayed powder (the portion that doesn't adhere to the workpiece) is directly wasted, and its utilization rate may be less than 50%. A recovery system efficiently collects over 99% of oversprayed powder, sieving it, and mixing it with fresh powder in a proportional manner for reuse, increasing the overall powder recovery rate to over 99.8%, significantly reducing the coating cost per product.

Reduced waste disposal costs: Powder treated as waste is not only wasteful in itself, but its collection, cleaning, and disposal require additional labor and costs. The recovery system fundamentally reduces solid waste generation, saving hidden costs.

2. Environmental Protection and Safety:

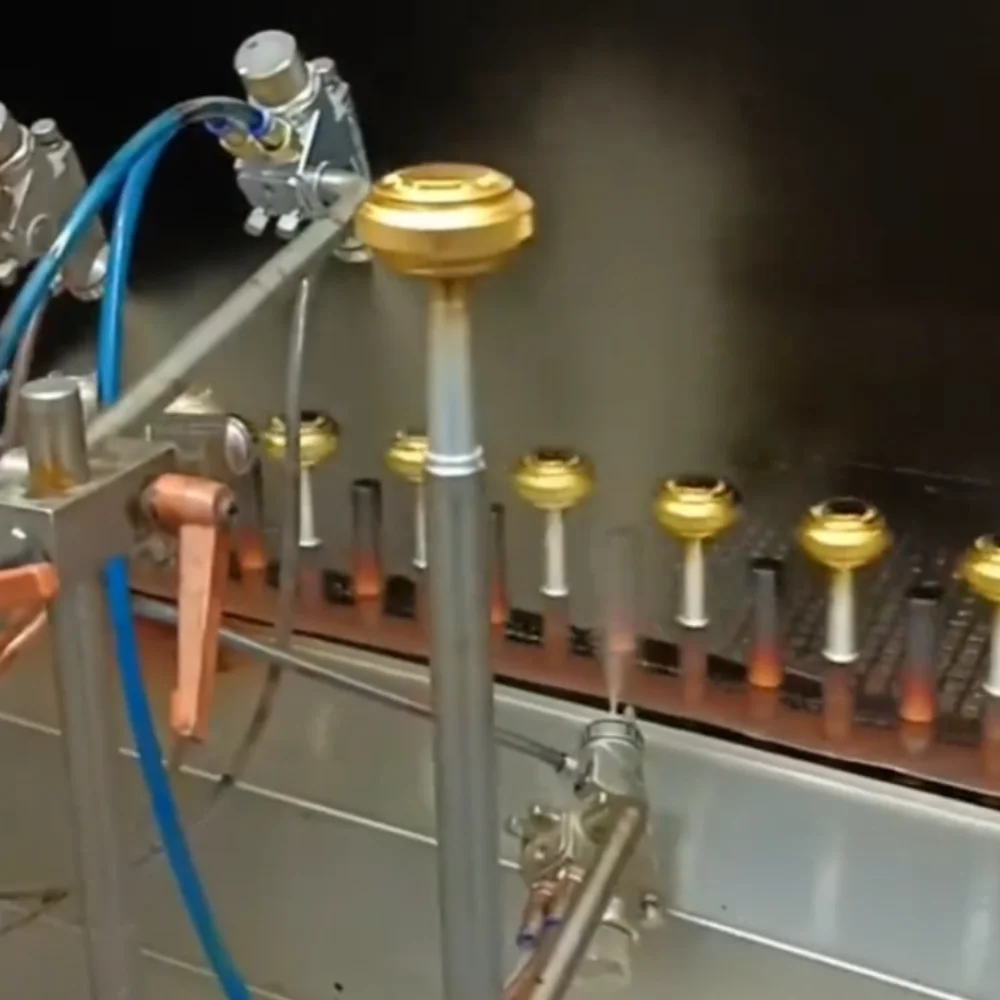

Achieve clean production and protect employee health. Airborne powder dust can pose a respiratory hazard to workers and, at certain concentrations, pose a risk of explosion. The recovery system uses negative pressure extraction to maintain clean air in the spray booth at all times, significantly improving the working environment, ensuring the health and safety of operators, and reducing occupational health risks and corporate safety risks.

Meeting Environmental Regulations and Fulfilling Social Responsibility: Global environmental regulations are becoming increasingly stringent, strictly prohibiting the direct emission of industrial dust. The powder recovery system ensures near-zero powder emissions during production, helping companies easily meet environmental regulations, avoid fines or production suspensions, and establish a positive image as a green manufacturing company.

3. Quality and Efficiency:

Maintain a healthy spray booth environment and enhance coating quality. If overspray powder is not removed promptly, it can form diffuse pollution within the spray booth. When changing colors or spraying different parts, this suspended residual powder can easily cause cross-contamination, resulting in surface defects such as discoloration and particles. A recycling system instantly removes excess powder, crucial for ensuring consistent and high-quality coatings.

Ensuring continuous and stable equipment operation: Excessive powder accumulation can contaminate precision equipment such as the spray robot, spray gun, and sensors, leading to frequent malfunctions and reduced accuracy. A recycling system provides a clean, stable operating environment for automated spraying equipment, reducing maintenance and downtime, and improving overall production efficiency.

4. The "Closed-Loop Logic" of Automated Production:

The core value of automated powder coating equipment lies in unmanned, highly efficient, continuous operation. Without a recycling system, production would require frequent interruptions for manual cleaning and maintenance, completely defeating the purpose of automated production. The recycling system and automated spraying equipment form a complete, self-circulating closed-loop system, the technological cornerstone for achieving truly "uninterrupted, efficient, automated production."

Thus, the powder recycling system and automated powder coating equipment are an inseparable, integrated whole. Installing a recycling system is not an expense, but an investment with a high return. It directly impacts a company's production costs, product quality, safety, environmental compliance, and automation level. Ignoring its importance will lead to uncontrolled powder costs, unstable product quality, poor working environment and frequent production interruptions, which will ultimately greatly reduce the investment value of the automatic spraying equipment.

Dongguan Automatic Coating Machine Helmet Coating Equipment Reciprocating Machine Motorcycle Helmet

IMLUCKY Aluminum Profile Coating Line Automatic Electrostatic Powder Coating Line System

IMLUCKY 32.5 Meters in Total Length with Oven, Stainless Steel Material Bottles Hardware Plastic Parts

IMLUCKY Electrostatic Spray Coating Assembly Line with Fully Automatic High-temperature Oven