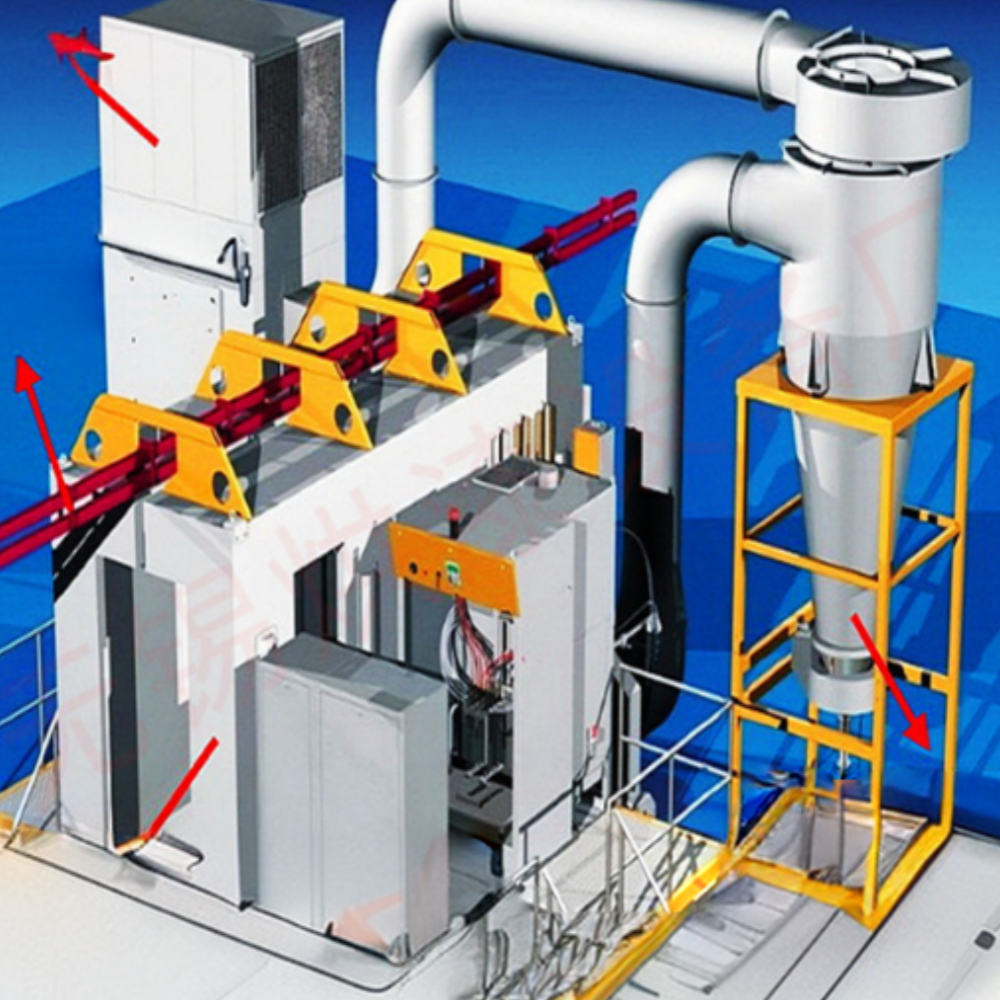

Shenzhen Qiheng Electronics Co., Ltd. designs booth systems for powder coating which are self-contained and efficient. These systems integrate components such as the booth structure, spraying apparatus, powder supply units, and ventilation systems into a single cohesive unit for polishing. The booth systems's fully enclosed dust scrubbed clean environment guarantees an impeccable and high caliber coating atmosphere. The company's exclusive patented technology derives from optimized powder use and superior quality coatings. From small scale to large scale production, the company's powder coating booth systems can be tailored to suit industrial requirements. For pricing information, please reach out to us