- Power: 380V

- Provide after service: Yes

- Operating weight: over 500KGS

- MOQ: 1pcs

- Product size: customized

- Exw: Guangzhou

- Delivery date: 45 working days

- Rated Voltage: 380V( customized optional)

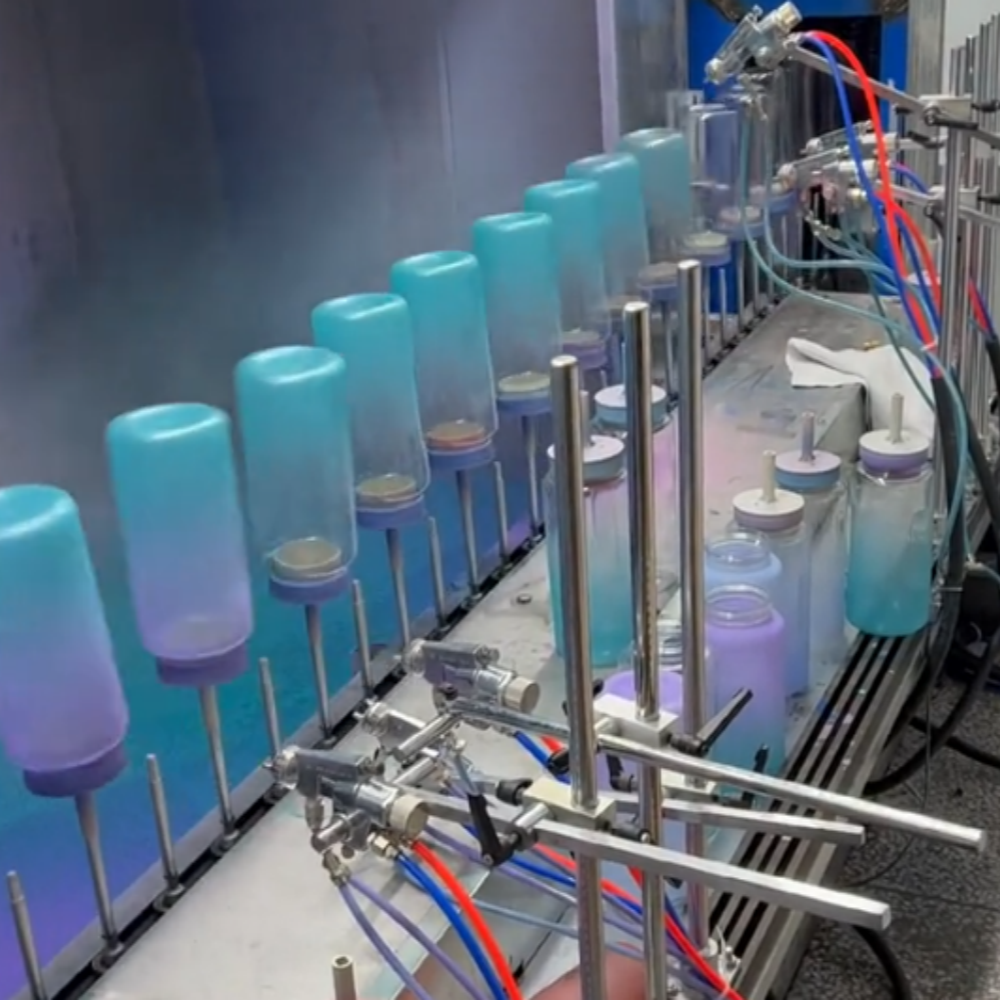

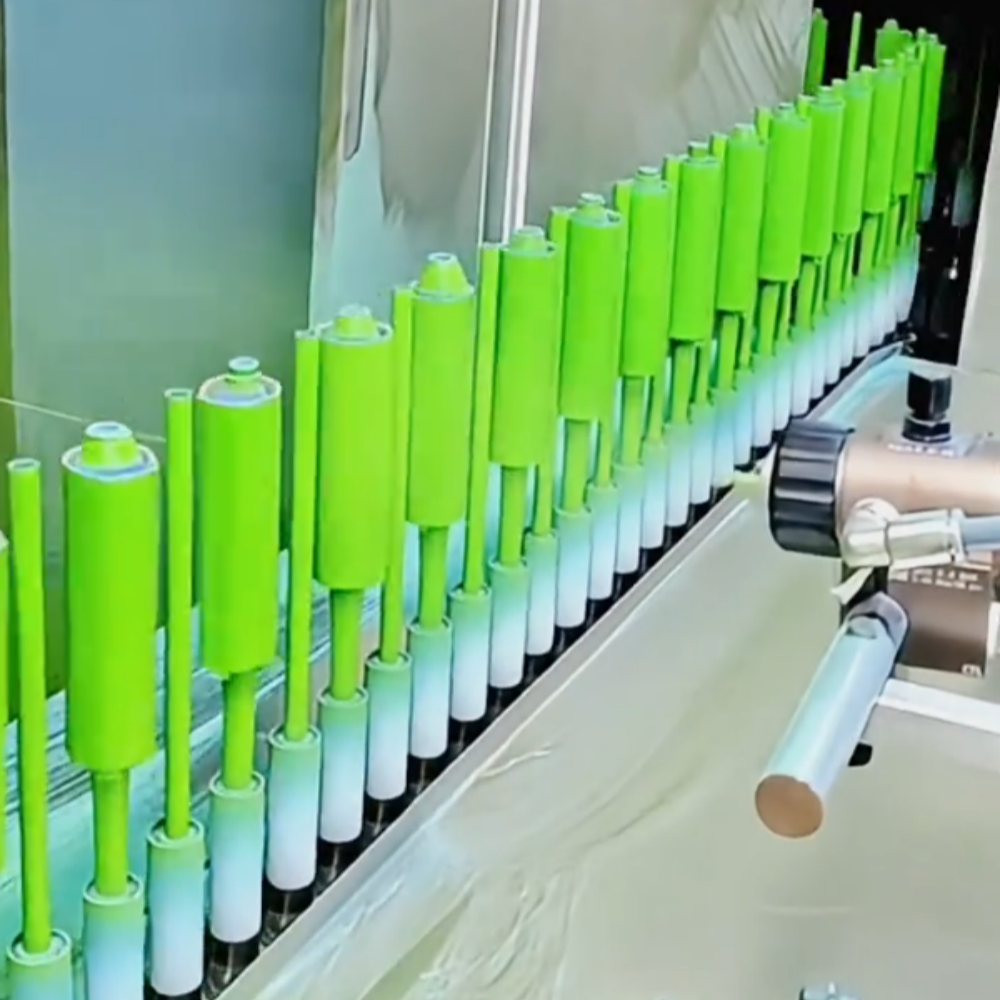

First of all, the wheel spraying machine is a high-tech intelligent spraying machine. Its emergence has brought revolutionary changes to the automotive industry. This machine can be controlled by a computer to accurately spray paint on the wheels, making the wheel surface smoother and more beautiful, and greatly improving the car's wear resistance and corrosion resistance. The wheel spraying machine can automatically adjust the spraying angle and spraying distance according to the shape and size of the wheel to ensure that the paint is evenly covered on the wheel surface.

Not only that, the wheel spraying machine also has high environmental protection performance. The paint particles produced during the spraying process are very small and will not cause pollution to the environment. In short, the emergence of wheel spraying machines not only improves the quality and appearance of automobile wheels, but also brings a more environmentally friendly and efficient production method to the automotive industry.

I. Core Components

A typical automatic spraying system consists of the following components:

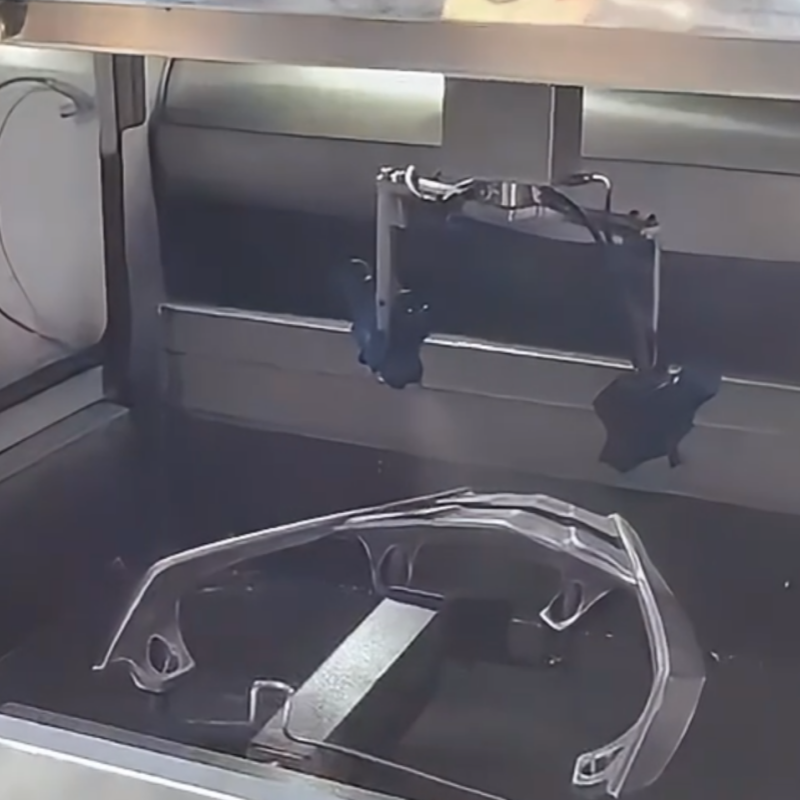

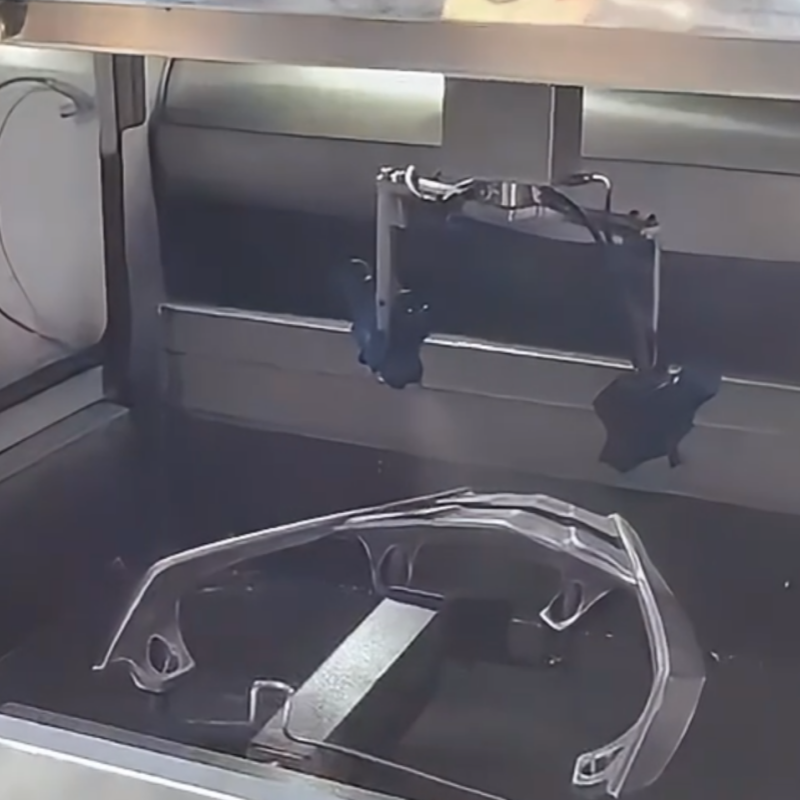

1. Machine Body:

This is typically a high-precision industrial robotic arm with six or eight axes. It offers high flexibility and range of motion, enabling it to cover the entire surface of complex workpieces. It utilizes an explosion-proof design, with sealed motors and wiring to prevent hazards posed by flammable and explosive coating environments.

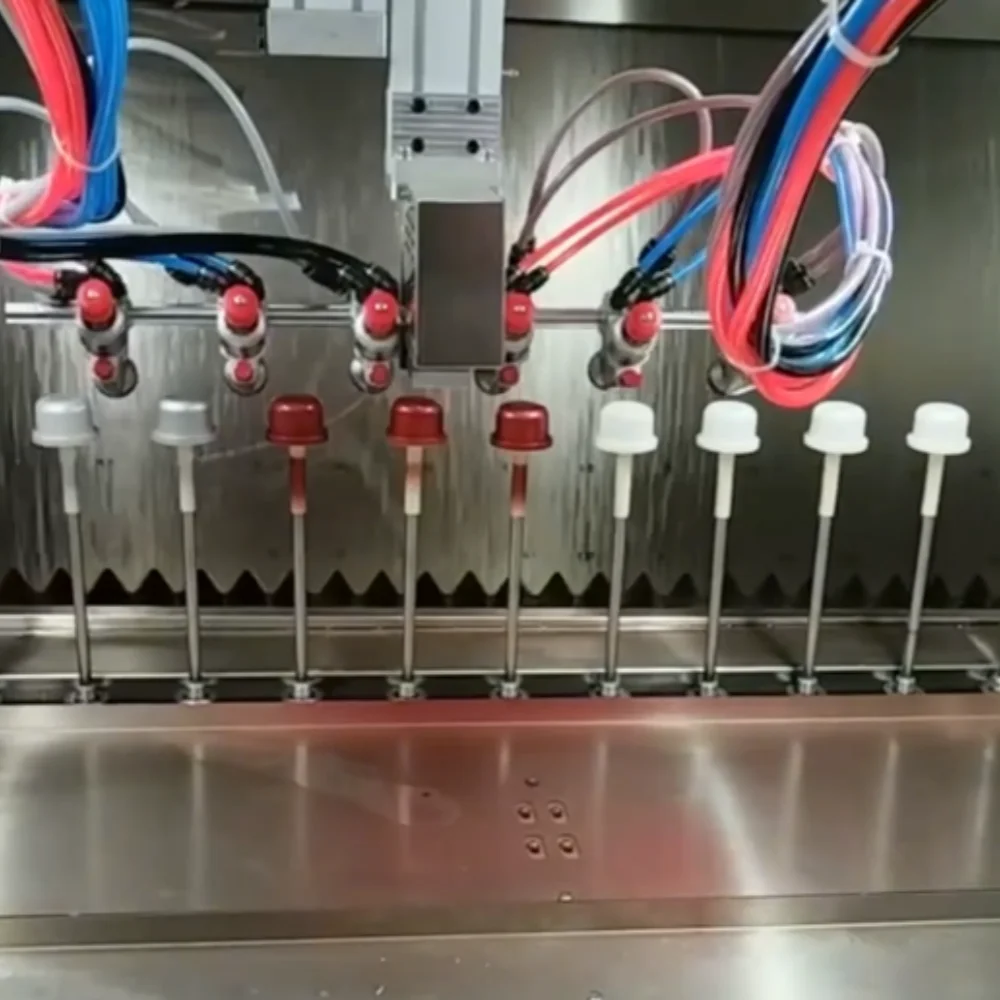

2. Spraying Tools:

This is the core component of the spraying process. Commonly used tools include:

Air spray guns: These use compressed air to atomize the coating. They are low-cost and widely applicable.

High-pressure airless spray guns: These use a high-pressure pump to apply extremely high pressure to the coating, atomizing it through a tiny nozzle. They are highly efficient and maximize coating utilization.

Electrostatic bell: Currently the most mainstream technology. The high-speed rotating bell generates centrifugal force to atomize the paint, while simultaneously applying high-voltage static electricity, which evenly attracts the charged paint particles to the grounded work surface. This significantly improves paint utilization and coating uniformity.

3. Feed System:

Includes a paint pump, pressure tank, feed pipe, pressure regulator, agitator, etc. Responsible for continuously, stably, and on-demand supply of paint to the spray gun, ensuring uniform viscosity and composition.

4. Control System:

The robot's brain, including the control cabinet and software. The operator programs (offline or online teaching) here, planning the robot's trajectory, the spray gun's on/off function, and the atomizer's parameters (flow rate, atomization pressure, electrostatic voltage, etc.).

Advanced systems can integrate visual recognition to automatically identify the workpiece's location and model and automatically invoke the appropriate program.

5. Safety and Protection System:

Explosion-proof System: The entire unit (robot, controller, cables) must comply with strict explosion-proof standards (such as ATEX).

Ventilation System: The spray booth requires strong downdraft or updraft ventilation to promptly remove volatile organic compounds and overspray mist.

Fire Protection System: Equipped with combustible gas detectors and automatic fire extinguishing devices.

Protective Fence: Physically separates the robot from personnel to prevent them from entering hazardous areas.

II. Core Advantages

Compared to traditional manual spraying, automated spray robots offer overwhelming advantages:

1. High Coating Quality and Consistency:

The robot's motion path, speed, spray gun distance, and angle are precisely repeatable, completely eliminating the uncertainty associated with manual operation and ensuring highly consistent appearance and film thickness for every product.

2. High Production Efficiency:

It can operate 24 hours a day, at speeds far exceeding those of manual labor, significantly increasing production capacity. It is particularly suitable for large-scale assembly line production.

3. Significant Cost Savings (Long-Term):

High Paint Utilization Rate: Electrostatic rotary cup technology, in particular, can increase paint utilization from 30%-50% manual paint utilization to over 80%-90%, directly saving significant material costs.

Low Labor Cost: One robot can replace two to four skilled spray painters, reducing associated management and welfare costs.

Low Scrap Rate: Consistent quality means less rework and scrap.

4. Improved Work Environment and Health and Safety:

Completely freeing workers from hazardous, flammable, and explosive spray environments, preventing occupational hazards (such as respiratory diseases) and eliminating major safety hazards.

5. Flexible Production:

By changing fixtures and calling different programs, the system can quickly adapt to spraying tasks for different models and batches of products, providing high flexibility.

III. Major Application Industries

Automotive Industry: The largest application area. Used for spraying primers, basecoats, and clearcoats on interior and exterior surfaces of vehicle bodies. *Aerospace: Used for high-standard painting of aircraft fuselages, wings, and components, as well as spraying specialty coatings (such as anti-corrosion coatings).

Electronics: Provides high-quality decorative coatings for mobile phones, computer cases, and other applications.

Furniture and Appliances: Sprays wood and metal paints on cabinets, refrigerators, washing machines, and other surfaces.

General Industry: Protective and decorative spraying of construction machinery, agricultural machinery, hardware, building materials, and other applications.

IV. Development Trends

1. Intelligence and Integration:

Deep integration with 3D vision and AI algorithms enables automatic workpiece recognition, path planning, and optimization of spray parameters.

Integration into the entire intelligent manufacturing system, enabling data exchange with management systems such as MES and ERP.

2. Green and Environmentally Friendly:

Use environmentally friendly materials such as water-based paints and high-solids paints to further reduce VOC emissions.

Optimize technology and pursue "zero overspray" to achieve ultimate material savings.

3. Simplification and Miniaturization:

Developing interfaces that are easier to program and operate, lowering the barrier to entry.

Launching lighter, more flexible collaborative spray robots to meet the needs of small and medium-sized enterprises.

Automated spray robots are therefore a prominent example of industrial automation technology in the surface treatment field. They are not only tools for improving product quality and production efficiency, but also key equipment in driving the manufacturing industry towards a green, safe, and intelligent future. With continuous technological advancements and declining costs, their application is expected to expand beyond large factories into a wider range of manufacturing sectors.

IMLUCKY Factory Direct Sales Assembly Line Total 18m Hardware Spraying Line Free Design Jig

IMLUCKY Automatic Gantry Hanging Production Line Surface Treatment Equipment for Switch Panel Electrophoresis Production Line

IMLUCKY Automatic MDF Powder Coating Line Automatic Powder Coating With Oven

IMLUCKY Hanging Electrostatic Spray Coating Equipment Industrial Spray Coating Production Line High Temperature Curing Oven