Electroplated Spraying

Electroplated parts spraying, or mirror-finish painting on electroplated substrates, is a surface treatment process that utilizes specialized paints and standardized manual electrostatic spraying techniques. This method creates a high-gloss, highly reflective mirror-like coating on electroplated surfaces, significantly enhancing gloss retention, abrasion resistance, and corrosion resistance. It ensures the long-term durability of the mirror effect.

The process involves uniformly applying coatings via a spray gun to form a protective film over the electroplated components. This layer safeguards the products against oxidation, corrosion, and wear, thereby improving overall product quality and extending service life.

During the painting process, it is essential to strictly control both the quality of the coating material and the working environment to ensure the quality and uniformity of the coating. At the same time, environmental protection requirements must be followed, including the use of coatings and processes that meet eco-friendly standards, so as to minimize environmental pollution.

The use of coatings with low volatile organic compound (VOC) content, combined with environmentally friendly atomization technology, precise coating control systems, and other advanced spraying equipment, can significantly improve coating utilization and operational efficiency. This approach reduces overspray, minimizes waste generation, decreases resource consumption, and lessens the environmental impact of waste materials.

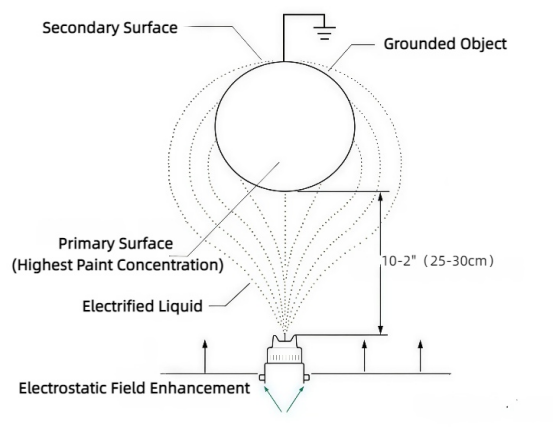

**Electrostatic Spraying** is a coating application method that utilizes the "electrostatic wrapping" phenomenon.

A high-voltage electrostatic charge is applied to the electrode needle of the spray gun, creating an electrostatic field between the gun and the grounded object. When the coating material is discharged through the electrostatic spray gun, it is atomized and simultaneously charged. These charged coating particles are then guided by the force of the electrostatic field, enabling a significantly higher proportion of the material to reach the grounded workpiece without deviating from the target or being carried away by surrounding airflow.

As a result, this process increases the transfer efficiency of electrostatic spraying, helping to substantially reduce costs, supports environmentally friendly spraying practices, and meets evolving production requirements.

Spraying Case Study

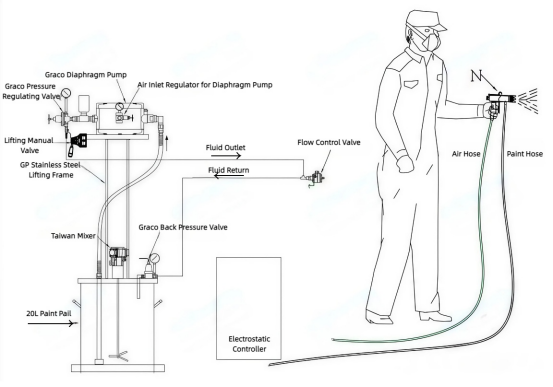

This application case involves mirror-finish spraying on electroplated parts. Using a manual air electrostatic spray gun, the process achieves high atomization and uniform coating consistency. It significantly reduces paint waste, alleviates environmental compliance pressure, and enhances production capacity — delivering excellent finish quality and exceptional application efficiency.

Based on the customer's spraying requirements, IMLUCKY technical specialists customized a complete solution according to the customer's needs. Configured product list:

- GRACO 308 Diaphragm Pump (USA)

- WIWA Manual Electrostatic Spray Gun

- Electrostatic Controller

- Pressure Regulating Valve

- Paint Hose

- Air Hose

- Pneumatic Mixer

- Isolation Cabinet

The Triton 308 air-operated diaphragm pump is employed to ensure stable delivery of paint and coatings, paired with a manual air electrostatic spray gun for coating electroplated components. Throughout the electrostatic spraying process, the electrostatic voltage remains stable, resulting in a uniform paint film and excellent wrap-around effect. This effectively reduces material costs, supports compliance with environmental policies, and increases production capacity. The optimized combination of the delivery pump and spray gun ensures consistent fluid pressure during operation, guaranteeing stable paint film quality. This leads to a smooth, even coating and improves both product appearance and spraying efficiency.

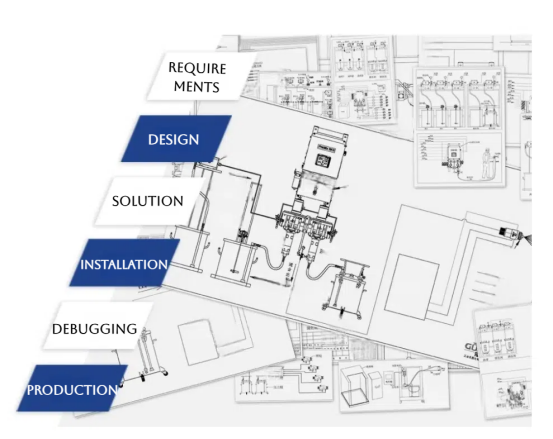

We provide tailored spraying solutions and comprehensive support for electroplated parts manufacturing, covering complete equipment from paint pumps and metering systems to spray guns. Whether you work with single- or two-component materials, require varying flow rates, or deal with diverse viscosity levels – we are equipped to meet your spraying needs.

IMLUCKY

Your Professional Spray Equipment Partner, Dedicated to Serving You.

We offer:

**Customized configurations to meet your specific needs**

**Support for online guidance or on-site installation and training**

**Technical assistance**

**Wherever coating is applied, IMLUCKY is there.**

With over 15 years of focused experience in China's spraying industry, IMLUCKY has always adhered to a clear mission: helping the manufacturing sector achieve energy-saving, high-efficiency, and environmentally friendly objectives.

As a factory specializing in spraying technology for more than 15 years, IMLUCKY is committed to providing world-class industrial products, coating technologies, and services to various sectors. Our professional team offers everything from basic spraying tools to complex automated and intelligent customized solutions.