The Advantages of Liquid Dipping Lines for Surface Treatment

How Liquid Dipping Lines Enhance Surface Treatment Efficiency

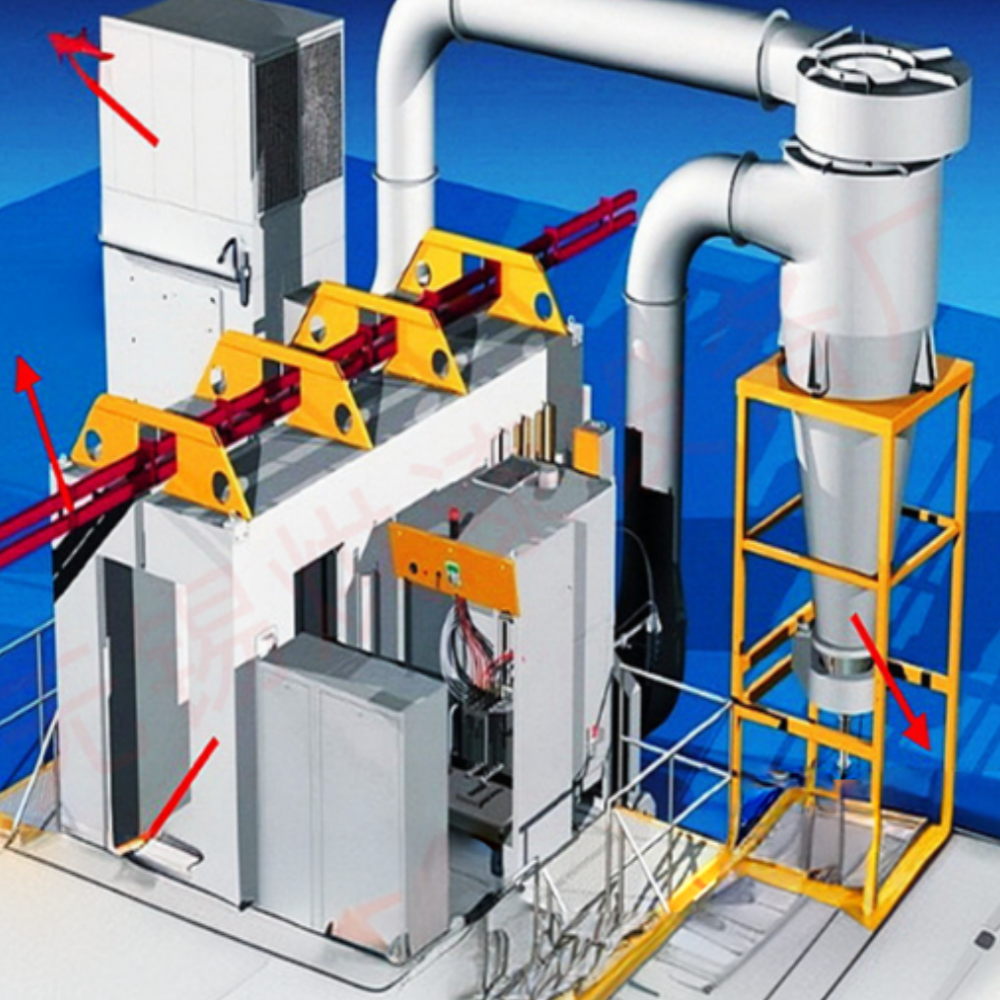

Streamlined Process: Immersion to Curing

Liquid dipping lines have become pretty efficient when it comes to surface treatments, covering all steps from getting parts wet to letting them ...

View More