Why Your Business Needs an Automatic Spray Paint System

Boosting Production Efficiency with Automatic Spray Systems

Reducing Material Waste Through Precision Application

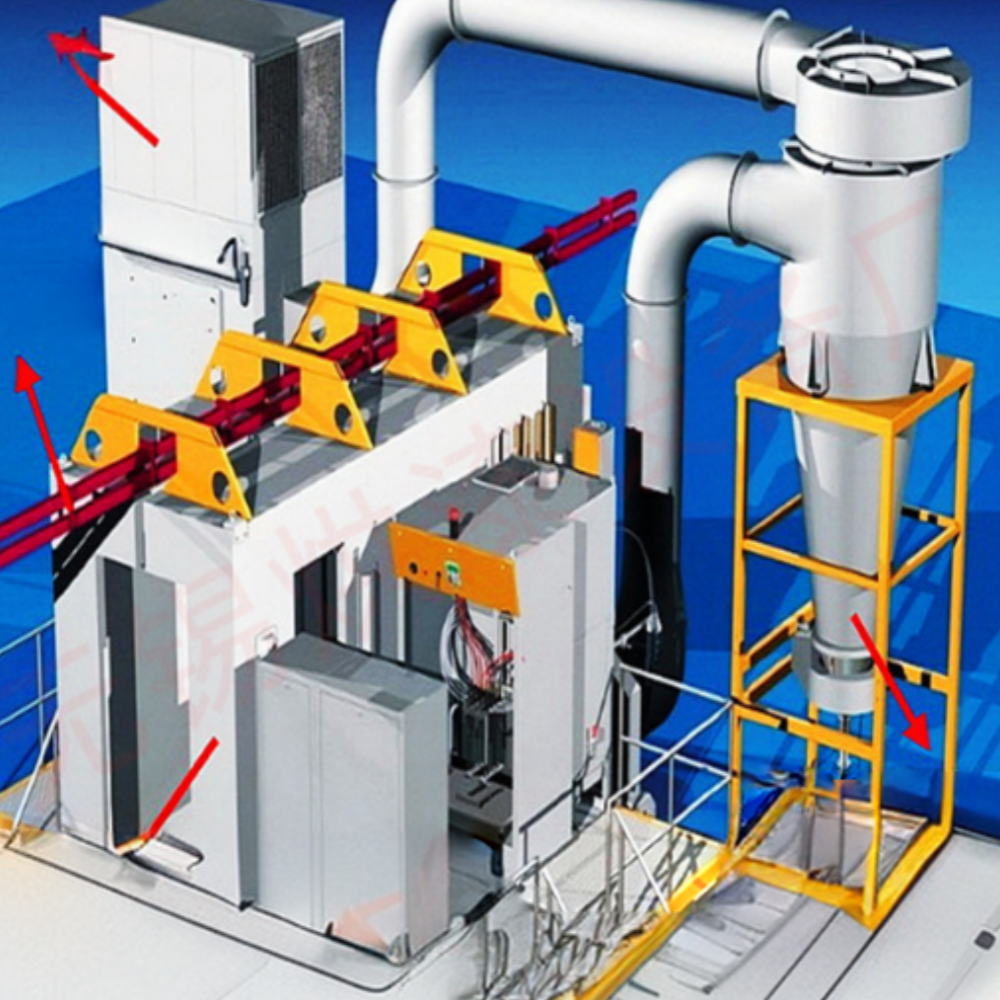

Automatic spray systems really make a difference in cutting down on wasted materials because they apply coatings so precisely. These s...

View More