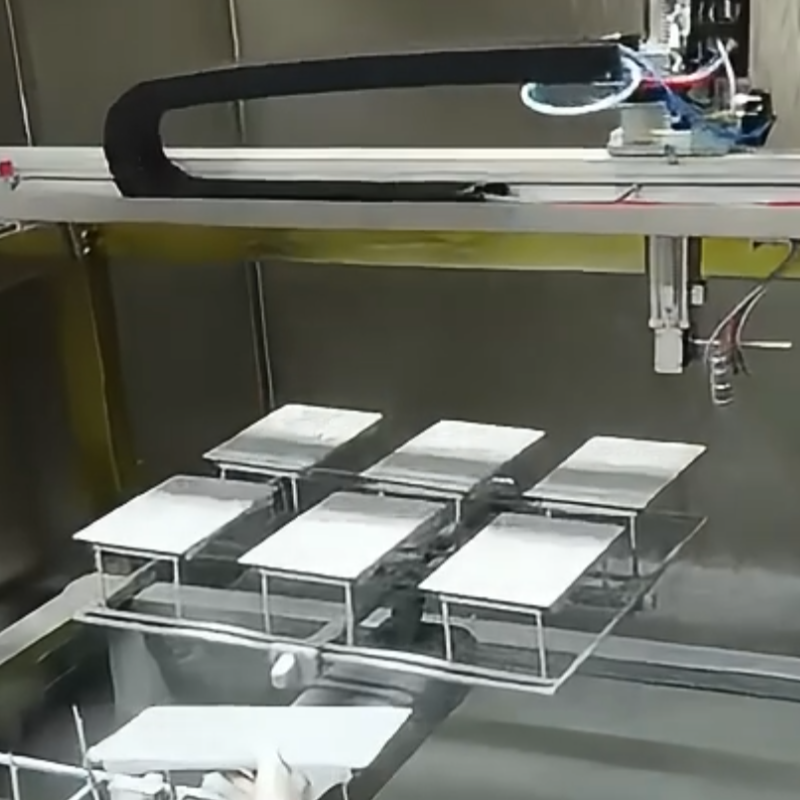

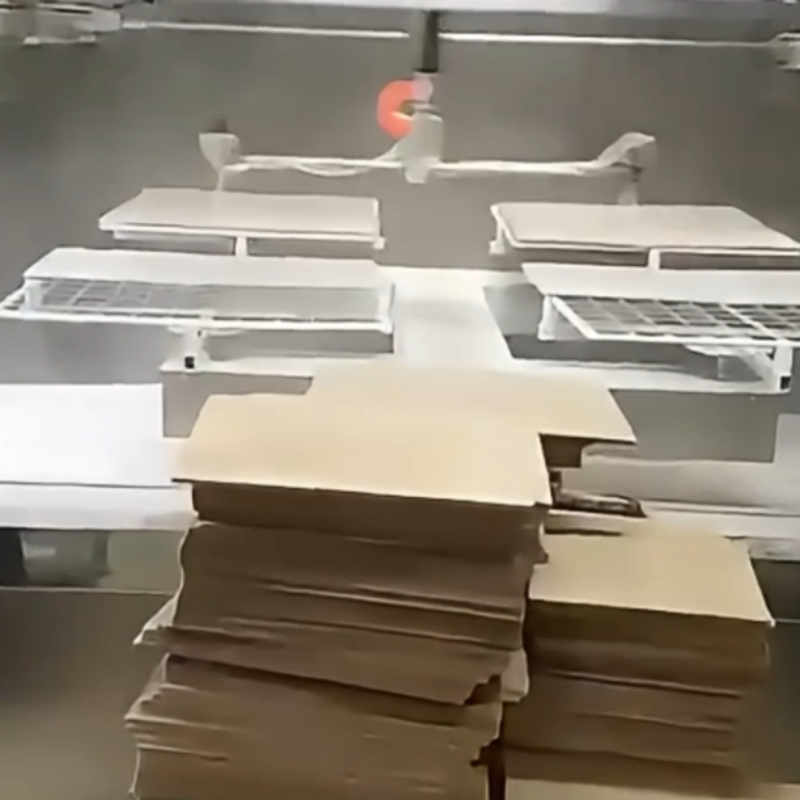

Shenzhen Qiheng Electronics Co., Ltd. offers industry-leading, high-efficiency spray systems. Their focus is on enhancing productivity and coating quality. Intelligent control systems optimize the spraying path for uniform coating distribution, and the company’s proprietary patented technology reduces the consumption of paint or powder materials, lowering production costs. The fast-acting components of their high-efficiency spray systems increase the speed of spraying while maintaining precision. These systems are seamlessly integrated with various conveyor systems for non-stop production. Reliable for the automotive, furniture, and electronics industries, these systems are an excellent option. Contact us if you would like to know the price.